Universal Molding Company

Universal Molding CompanyRequest A Quote

Downey, CA | 562-940-0300Universal Molding Company (UMC) is a leading manufacturer of custom roll formed parts. Founded in 1942, the company has over 75 years of experience in providing high-quality roll formed parts to a wide range of industries, including automotive, construction, agriculture, and electronics. UMC specializes in the roll forming process, which involves feeding flat metal coils through a series of rolls to gradually shape and form the metal into the desired profile. This process allows for a high degree of customization, with the ability to create parts in a variety of shapes, sizes, and materials. The company's product line includes a wide range of roll formed parts, including channels, angles, panels, tubing, and more. These parts can be produced in a variety of metals, including steel, aluminum, brass, copper, and stainless steel, to meet the specific requirements of each customer's application. UMC is known for its commitment to quality, with a strong focus on continuous improvement and customer satisfaction. The company's ISO 9001:2015 certification demonstrates its dedication to meeting the highest standards of quality and consistency. In addition to its manufacturing capabilities, UMC offers a range of value-added services to its customers. These services include design and engineering support, prototyping, finishing and coating, and custom packaging and labeling. UMC's experienced team of engineers and technicians work closely with customers to understand their specific needs and provide customized solutions that meet their exact requirements. The company's state-of-the-art equipment and advanced technology allow for efficient production and quick turnaround times. Overall, Universal Molding Company's focus on quality, customization, and customer satisfaction make it a trusted partner for companies in a wide range of industries looking for high-quality roll formed parts and exceptional service.

Cold Headed Parts

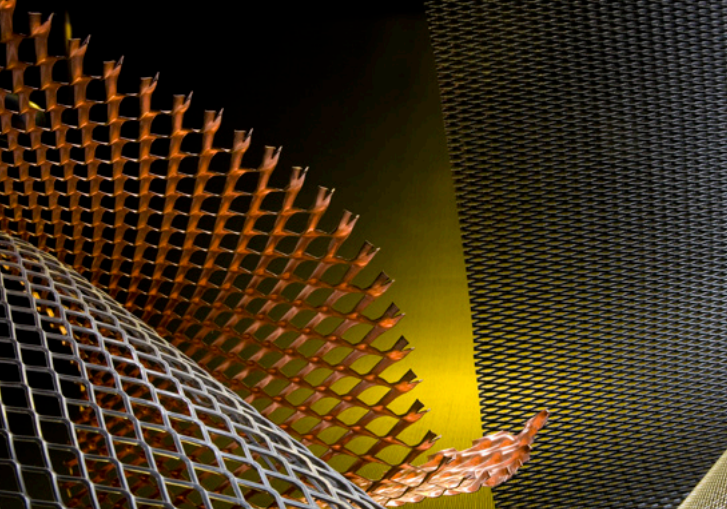

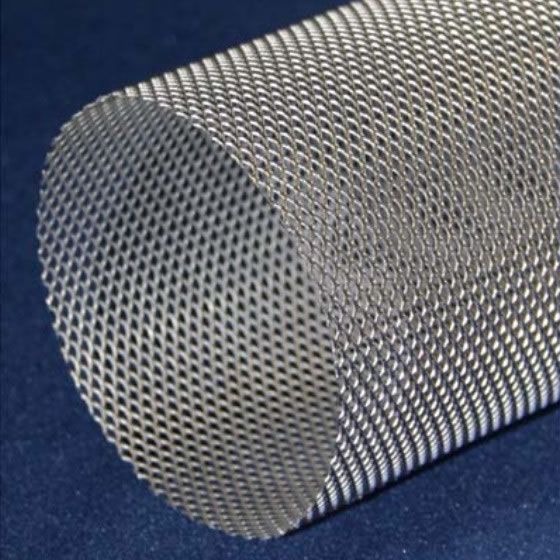

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

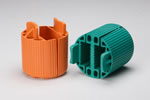

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services