Metal rings are used to embellish door hardware, used on key chains and in manhole and utility channel access points. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

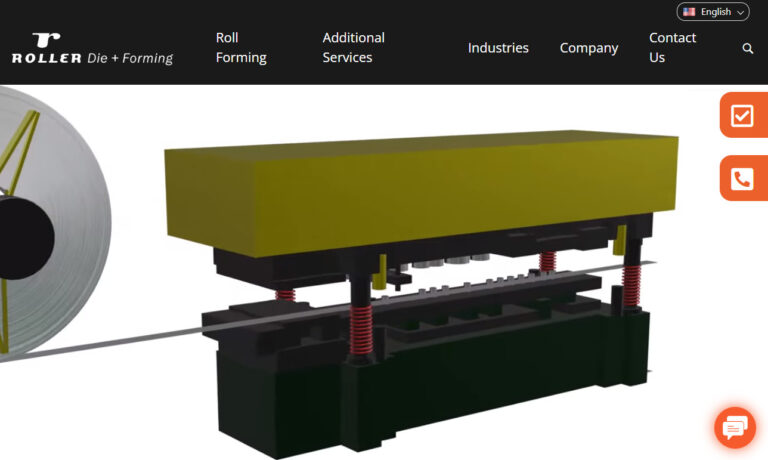

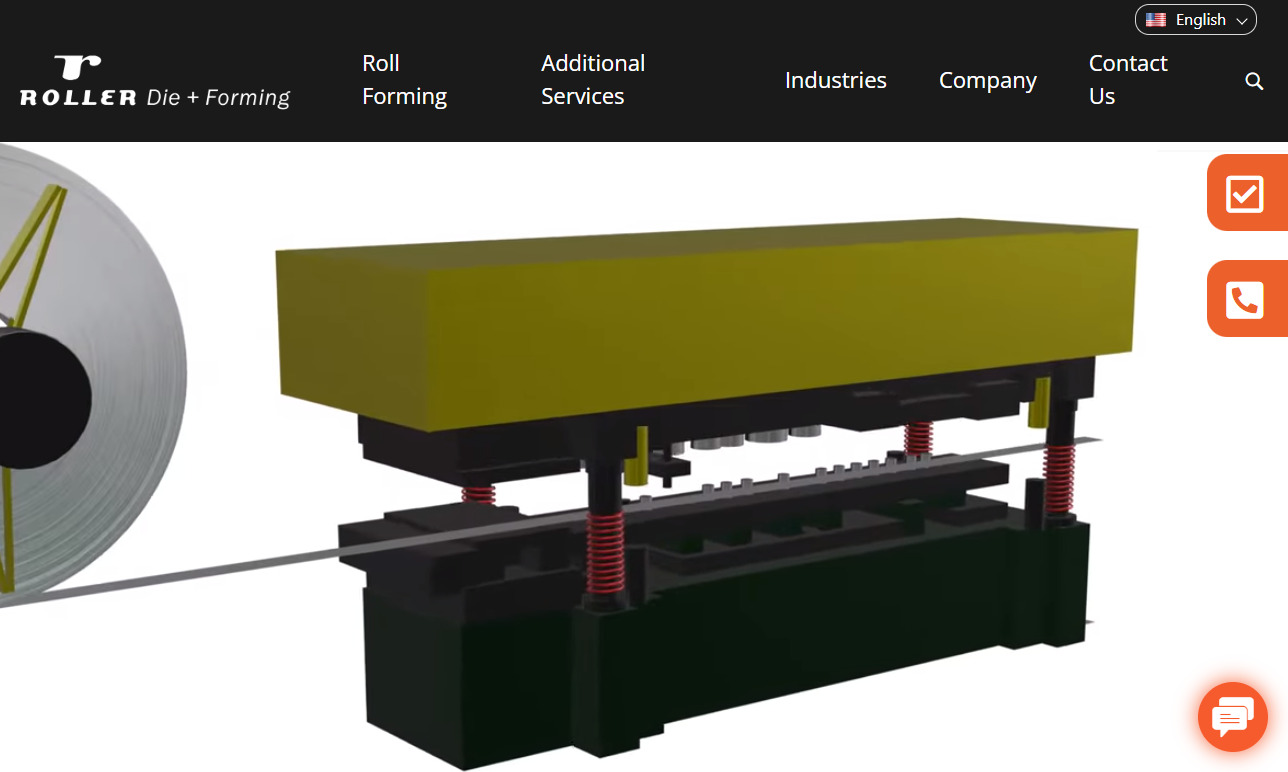

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Metal Ring Companies

The vast variety of metal ring applications extends to clamping, sealing, joining or trimming items such as drums and lids, street signals or mirrors. Children's toys, electronics, vehicles, furniture, appliances and many other products make use of metal rings in some way. A metal ring can be as small as a few inches in diameter or as large as ten feet in diameter.

While metal rings can be made for low-demand applications, certain industrial consumers of metal rings require their rings to meet specific standards of durability, corrosion resistance and other qualities. Chemical producers, oil and gas companies, aerospace products manufacturers, military contractors and other companies that put metal rings to work in demanding applications must be assured that their rings will not fail.

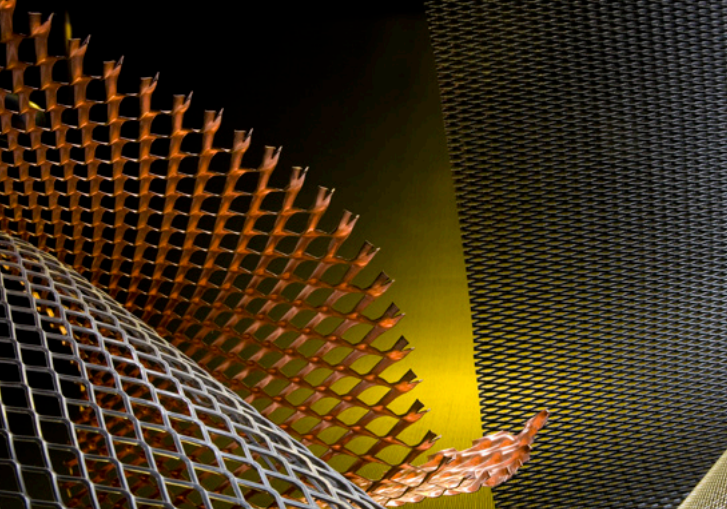

For such applications, steel is often the ring material of choice. Brass, aluminum, copper and zinc are other common materials used in the fabrication of metal rings.

There are a few processes by which metal rings are fabricated. The simplest, least precise way to make a metal ring would be to take a sheet or strip of metal, cut it to size, bend it by hand and weld the edges together. This is hardly a sustainable method because of its inefficiency and imprecision.

Roll forming is the process that most closely approximates the hand-bending method, but it eliminates those inefficiencies. A roll former is a long, narrow machine that features a series of spinning rollers. A long, preprocessed metal strip is fed into the receiving end of the roll former where it is caught by the first set of spinning rollers. These rollers fit tightly around the contours of the metal, and after having drawn the metal in, they push it to the next set of rollers.

Each subsequent set of rollers is configured a slightly different way, and as the metal strip is forced through them, its shape changes. In metal ring roll-forming, the rollers make the metal strip take a circular shape. Because no heat or welding is involved in roll-forming, roll-formed metal rings often emerge in a U shape or a similar shape. For this reason they are generally only suitable for uses in which they can be clamped shut with fasteners or by other means.

Cold Headed Parts

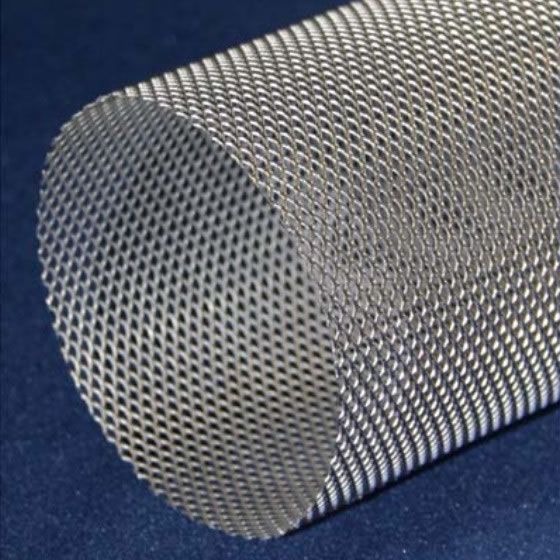

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

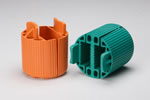

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services