Device Technologies, Inc.

Device Technologies, Inc.Request A Quote

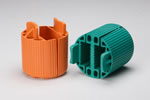

Southborough, MA | 508-229-2000DTi offers best in class grommet edging wire protection, edge trim, enclosure/door seals, cable/fiber management & metal coating services. Request free samples on site. Since 1984 we’ve supported manufacturers in commercial & military aerospace, rail, auto, IT/data centers, telecom, HVAC, medical & power. * Grommet edging: Spring-Fast® prevents data loss from chafe. It replaces the old, slow & costly multi step glue process used with nylon grommets. It delivers proven best in class performance with 49% lower install costs & a 9.5X efficiency improvement. Highly effective self locking nylon clad metal substrate snaps onto an edge with finger pressure. *Seals: Seal-Fast seals protect your vital equipment from weather, temperature, dust or moisture. Its single piece construction snaps on easily with strong edge retention. 100’s of U.S. produced off the shelf profiles available in PVC/EPDM, EPDM, and Silicone with/out a steel substrate. *Cable management: Fast-Drop® radius control modules aka cable waterfalls prevent data loss & help you access, organize, rewire & troubleshoot fiber networks to save time & money. The patented clip on design makes it faster to modify existing racks or set up new racks. * Protect-Fast sleeving & wrap is a tough, lightweight flexible containment & protection solution that protects wires, wire harnesses, cables or hoses from abrasion & cutting. They help in troubleshooting & refitting. General or Advanced Use products available. *Wire coating Services include polymer/powder magnet wire or for functional/decorative applications. Traditional enamel magnet wire & Kapton tape wrapping, and high temperature magnet wire for HEV/EV motor winding/high draw applications. DTi-GmbH is DTi’s European hub. Contact Meike Kurzak in Hamburg +49 40 350 85 128 Certifications: UL94 V-0, FAR 25.853, Mil-Std-1344, RoHS, BICSI, NEBS, & DFARS. ISO 9001:2015 & AS 9100-D Order free samples on site or call us today.

Cold Headed Parts

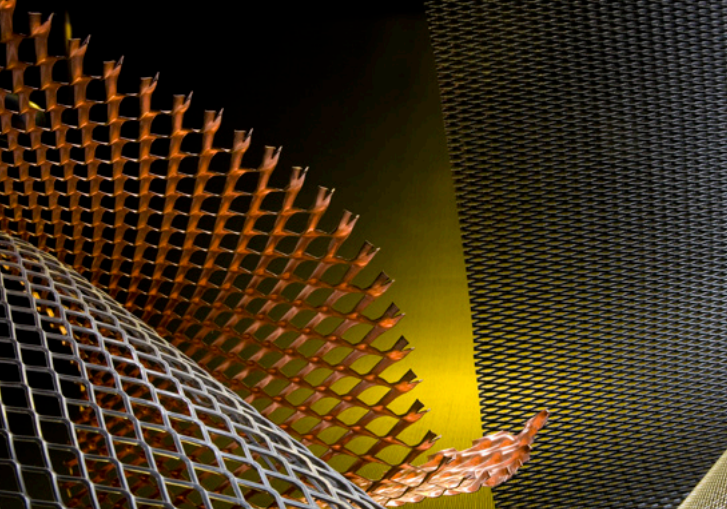

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

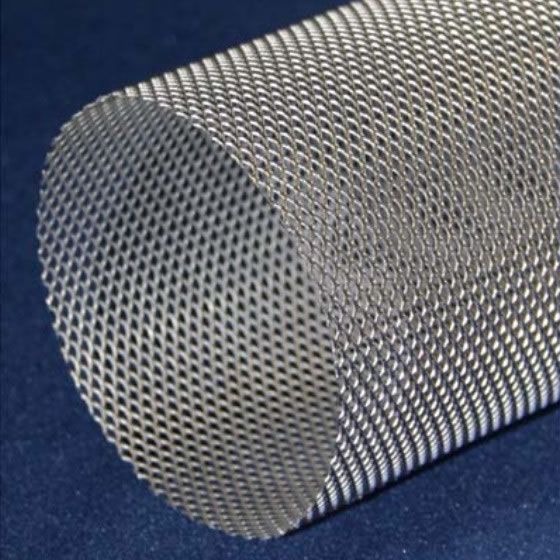

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services