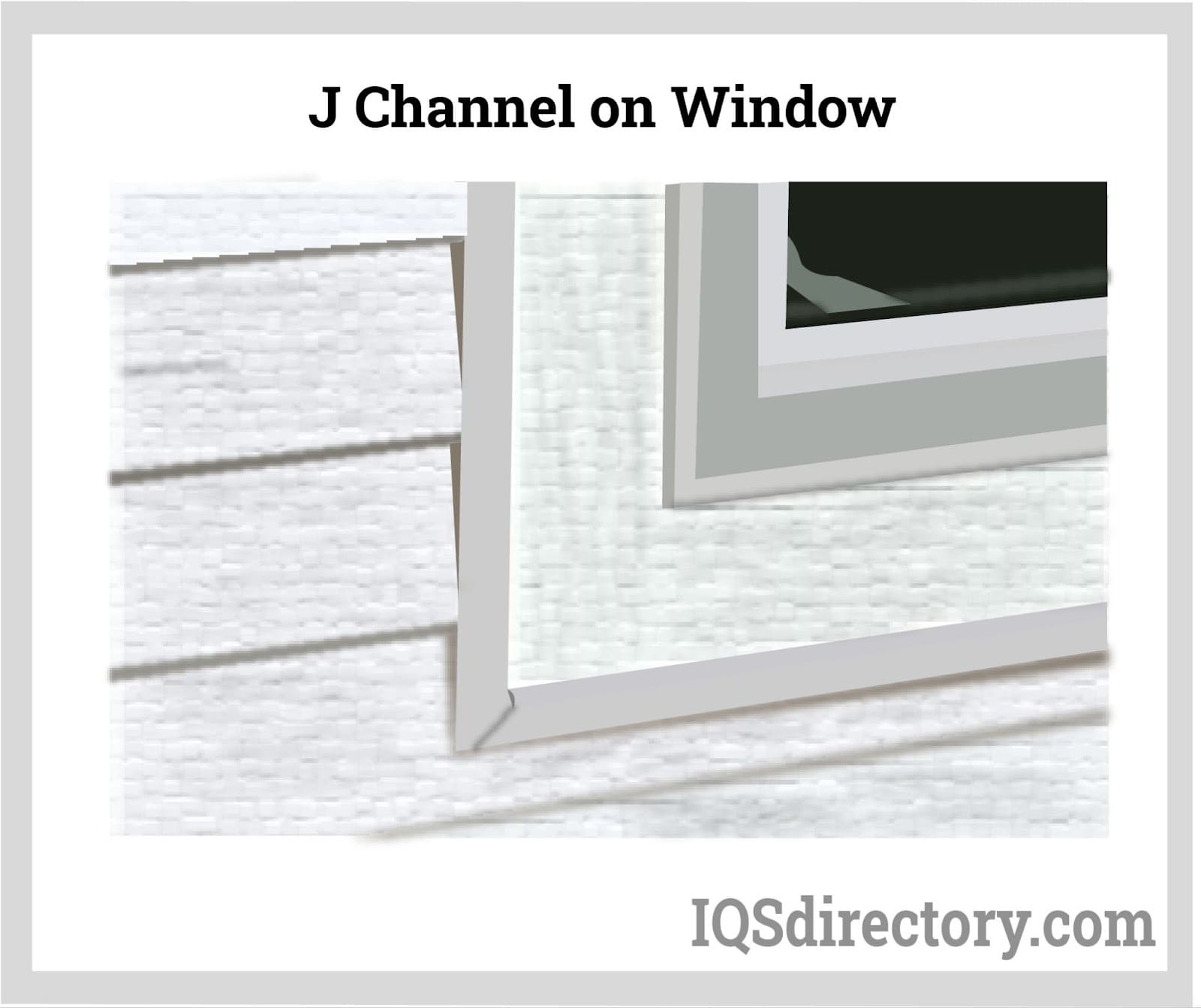

Aluminum, steel, and plastic are a few of the materials used to make J-channels. The trim around windows, doors, and the border of gables is where J-channels are most frequently employed as a finishing touch. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More J Channel Companies

What are J Channels?

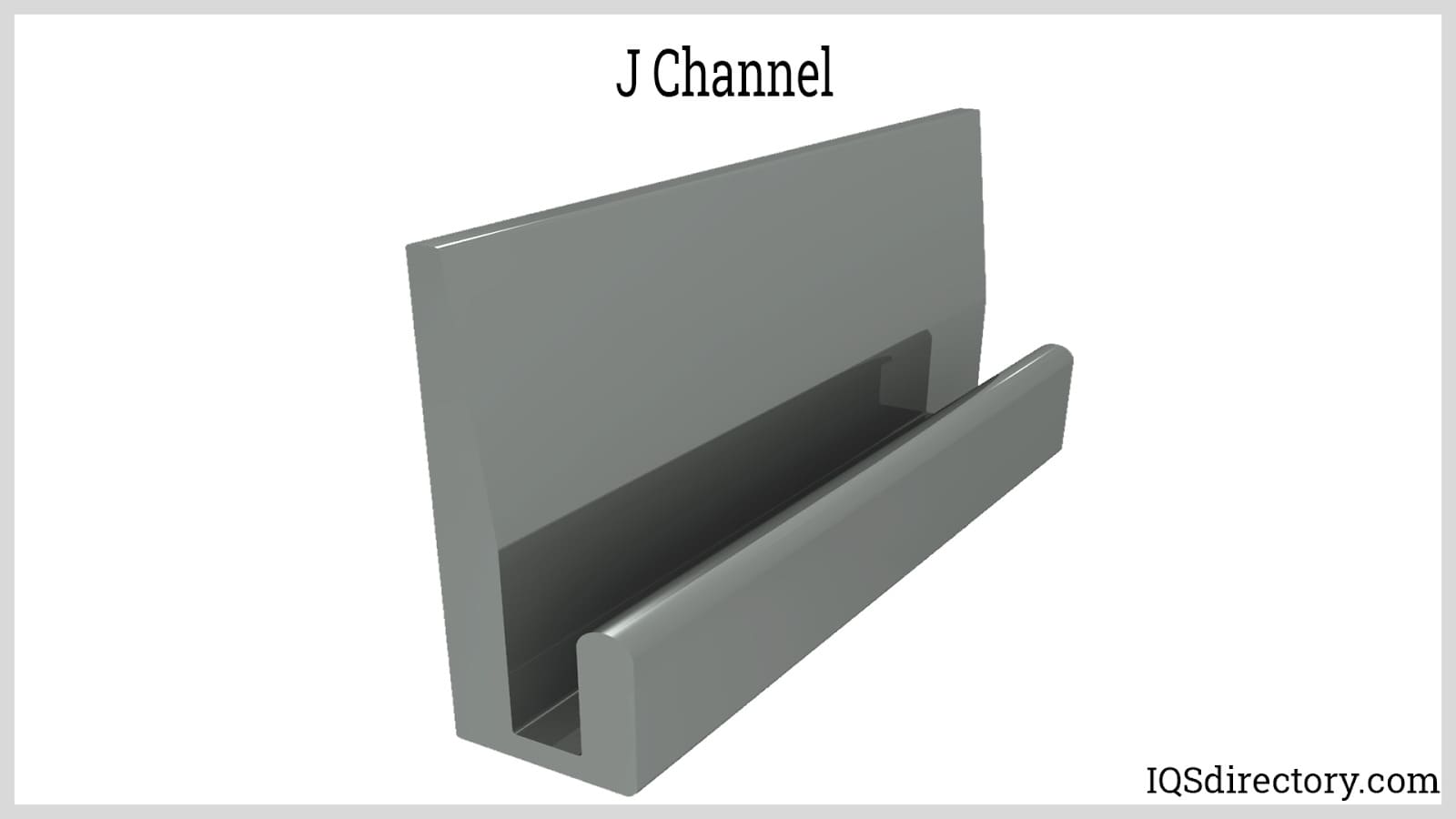

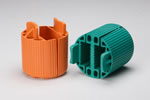

Most J-channels are simple to install because of the hooked J shape on the end of the flange. They can be installed by rapidly trimming them down to the required shape and then snapping them into place. A J-channel is configured by making one of the channel's sides longer than the other, resulting in a profile that resembles the letter J.

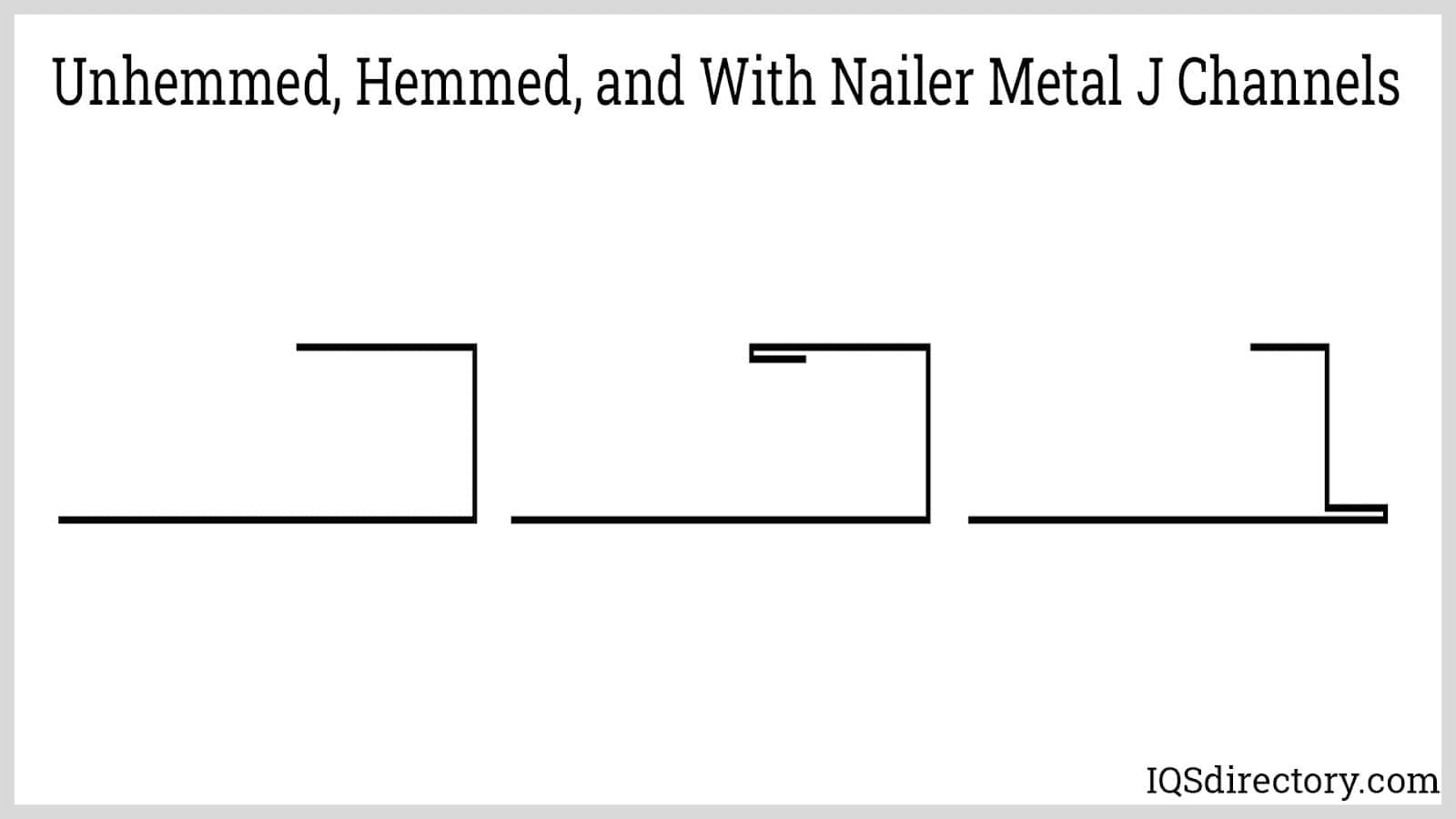

Numerous types of J-channels are created to fulfill a range of application requirements, even if a fundamental J-channel comes in several sizes and purposes. The three most popular types are the straightforward J channel without a hem, the J channel with a hem, and the J-channel with a flat piece that may be screwed or nailed on.

J-channels are offered in various lengths, ranging from a few feet to over 20 feet (6 m), just like other metal channels.

Manufacturing Process of J Channels

Many manufacturers create all-weather J-channels for hardware store sales. To match or enhance existing siding on a house, these can be covered with a variety of finishes. For instance, certain J-channels have a brown, grainy texture that, when placed, gives the appearance of wood trim.

As a result, installing a J-channel is quicker and less expensive than installing genuine wood, and it won't rot over time when it is exposed to moisture. J-channels are also utilized indoors to provide a decorative accent around the inside of window frames or other enclosures.

J-channels are made using a straightforward procedure, but this procedure relies on the materials used. For example, if plastic is used for production, the hot liquid is shaped into a J-channel in a mold as it cools. Then, shorter fragments of these lengthy works can be created.

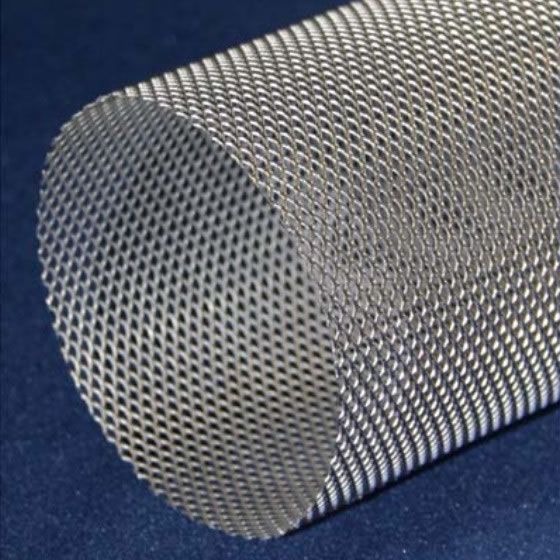

If sheet metal is used, the J-channel will be forced into the proper shape by a press in a fabrication facility using either hot or cold roll forming to impart slow, even pressure on the metal. Since this is a quick production method, producers may swiftly assemble J-channels and dispatch them to suppliers for resale or contractor installation.

Some manufacturers will even offer to design and develop custom J-channels for special applications or construction projects where the proportions are unusual.

Materials Used to Make J Channels

- Stainless steel is the perfect material for roll forming metal channels due to its different grades. Stainless steel comes in several grades, some of which have greater traits and attributes. The mechanical characteristics, corrosion resistance, and appealing appearance of stainless steel are the key justifications for utilizing it. Due to its corrosion and rust resistance, stainless steel has become a standard in producing goods for industries that need the highest levels of sanitation and cleanliness. Frequently used stainless steel grades include 304 and 316, with 304 being the more popular. Because stainless steel is alloyed with chromium and nickel, which gives it its resistance to oxidation and corrosion, it is incredibly strong.

- For metal channels, aluminum is the ideal material due to its strength and versatility. Despite not having the same tensile strength as steel, it provides sufficient stability to be employed as a support in some situations. Frame extensions, light poles, lighting fixtures, window and door frames, connectors, and lightweight ladders all use aluminum channels. Because of their good conductivity, metal channels made of aluminum are utilized as heat conductors and reflectors. When aluminum is exposed to air, an oxide coating forms that is typically sufficient for protection against corrosion and dangerous circumstances. Having additional protection while dealing with harsh situations, which the right finish can offer, is vital.

Applications of J Channels

- Sign hangers and holders

- Separators & decorative trim

- Photo frames

- Wire management cable organization

- Conductor bar protectors & bus bar insulators

Choosing the Correct J-Channel Supplier

To make sure you have the most positive outcome when purchasing J-channels from a J-channel supplier, it is important to compare at least 5 suppliers using our J-channel directory. Each J-channel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each J-channel business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple J-channel businesses with the same quote.

Cold Headed Parts

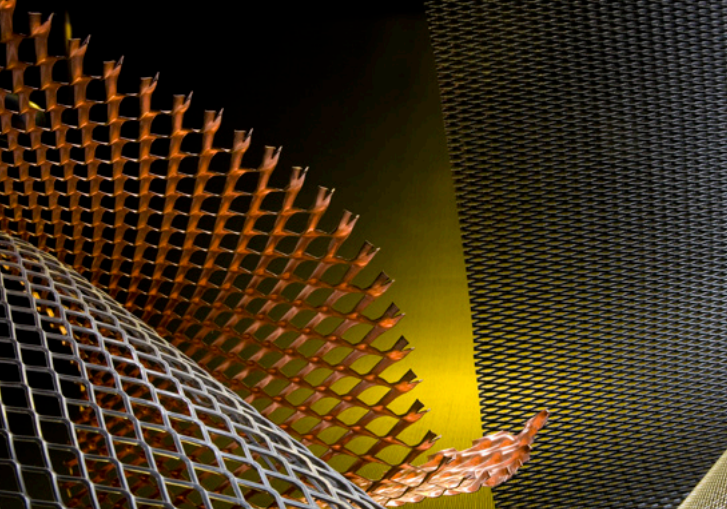

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services