Steel channels are made with hot-rolled carbon steel in the shape of a “C” with inner radius edges on the bottom and horizontal flanges on the top. Two parallel or tapered flanges and a large web make up a steel channel. Due to their structural strength, steel channels are used to create braces and frames for buildings, along with supports for various machines and large machinery. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

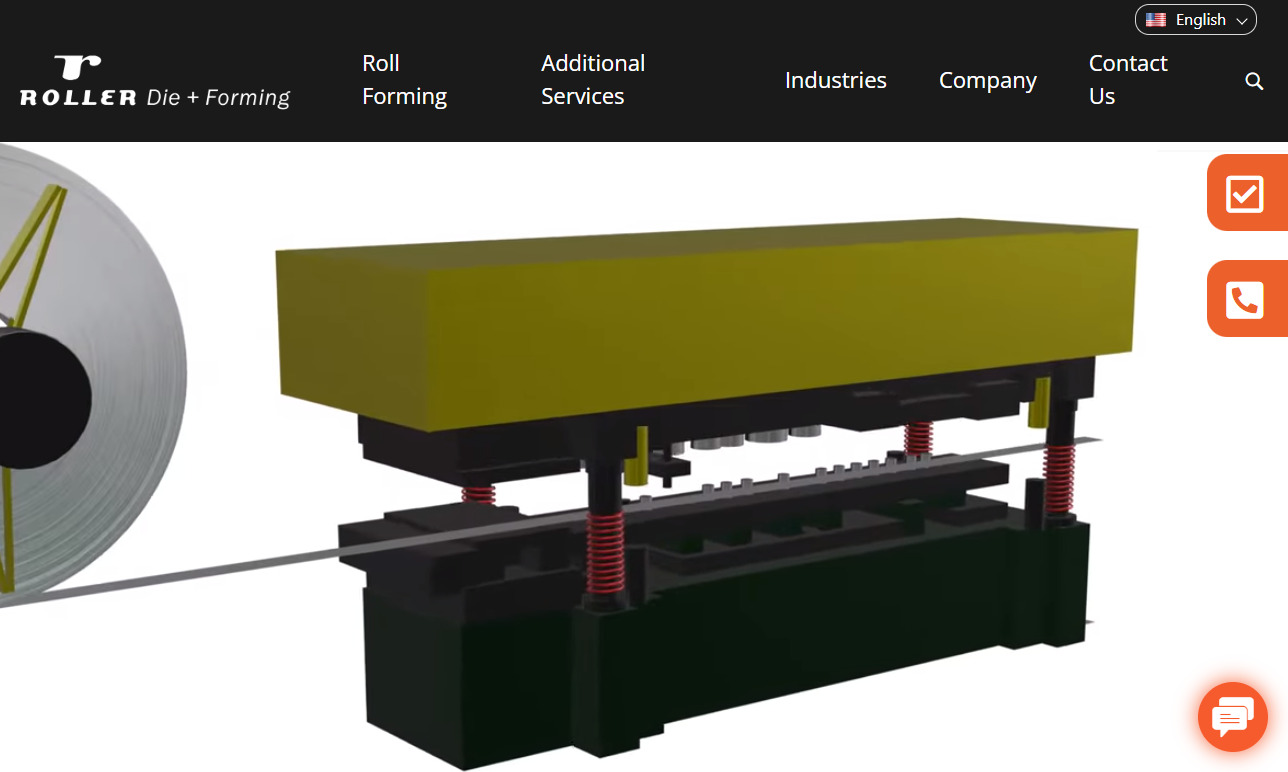

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Steel Channel Companies

Placing steel channels between 2 sections of plasterboard walls allows sound absorption in the construction sector. The channels reduce sound waves by dampening the vibrations caused by noise whenever the walls vibrate as a result of noise on every side of the wall. This use for steel channels, which are incredibly durable and robust, is just one of many.

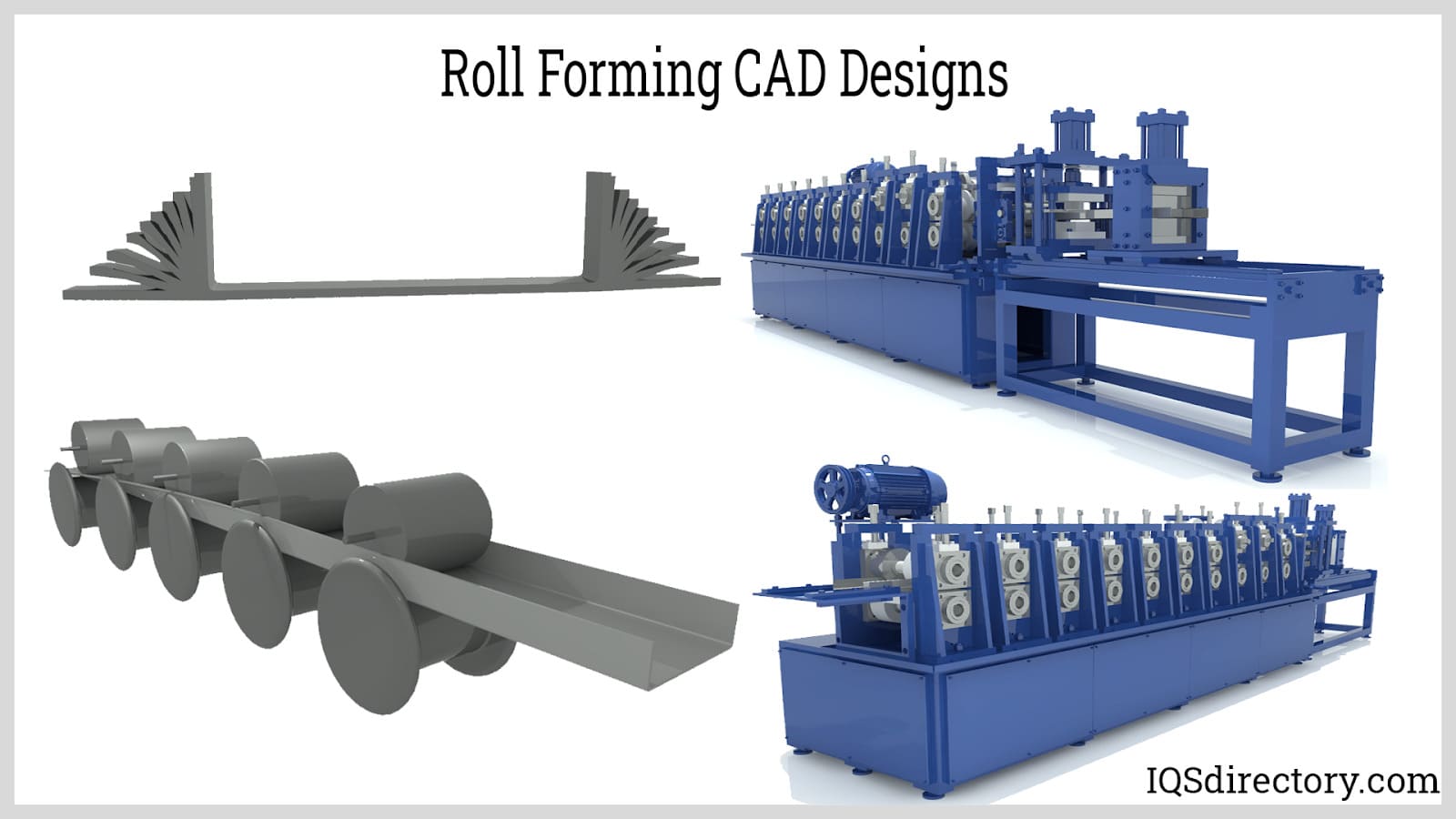

Manufacturing of Steel Channels

Steel channels feature radius-defined inner corners. This gives them the strength and stiffness required to support building projects and steel angles. They're easy to manufacture with the right tools and ratios. Typically, steel channels are produced to ASTM 36 dimensional requirements. Following hot rolling, steel channels are typically subjected to additional inline manufacturing. After manufacture, they are painted or galvanized to render them corrosion-resistant. Steel channels can be machined, drilled, or cut to particular dimensions. They are also simply wieldable. Large channels are frequently made using the laser fusion process.

Process of Hot Rolling Steel

Hot rolling is a metallurgical technique that occurs above the temperature at which the material recrystallizes. Hot-rolled metals often have unidirectional mechanical characteristics and frequently sustain residual stresses brought on by deformation. On the other hand, non-metallic inclusions occasionally carry directionality. In addition, many residual stresses are produced by non-uniform cooling, which is typical in designs such as I-beams and H-beams that have non-uniform cross-sections.

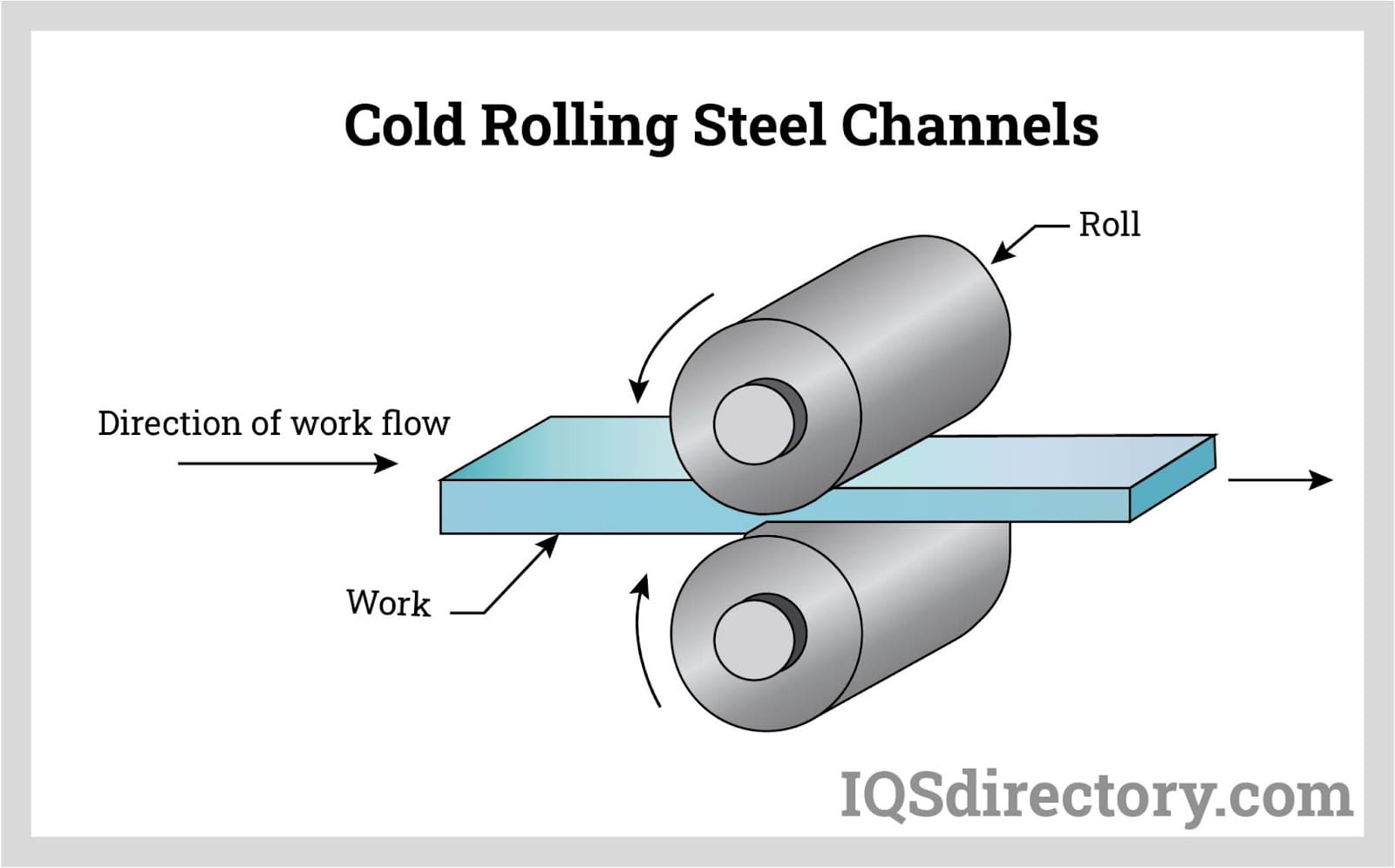

Cold Rolling of Steel

During cold rolling, the metal is rolled lower than its recrystallization temperature (typically room temperature). This process enhances the surface quality and maintains tighter tolerances. The use of multiple or cluster mills is justified by the smaller size and increased strength of the workpieces compared to hot-rolled stock. Cold-rolled goods, which are frequently tinier than their hot-rolled equivalents, include sheets, strips, and rods.

Types of Steel Channels

U Steel Channels

All hole drilling and notching operations previously carried out during the pre-punch process may be completed by inline post-fabrication dies. As a result, fewer dies are required, and the notching sites can have tighter tolerances without experiencing distortion, which would happen if the U channel or J channel were pre-punched and subsequently bent.

Inline fabricating with tight tolerance and higher speed requires highly developed straight-flying die accelerators and die amplifiers that use precise length measuring systems in the pre-punching and post-punching presses. The die accelerator may perform pre-drilling and post. Punching/cutoff presses simultaneously and up to 12 different tasks in the same die.

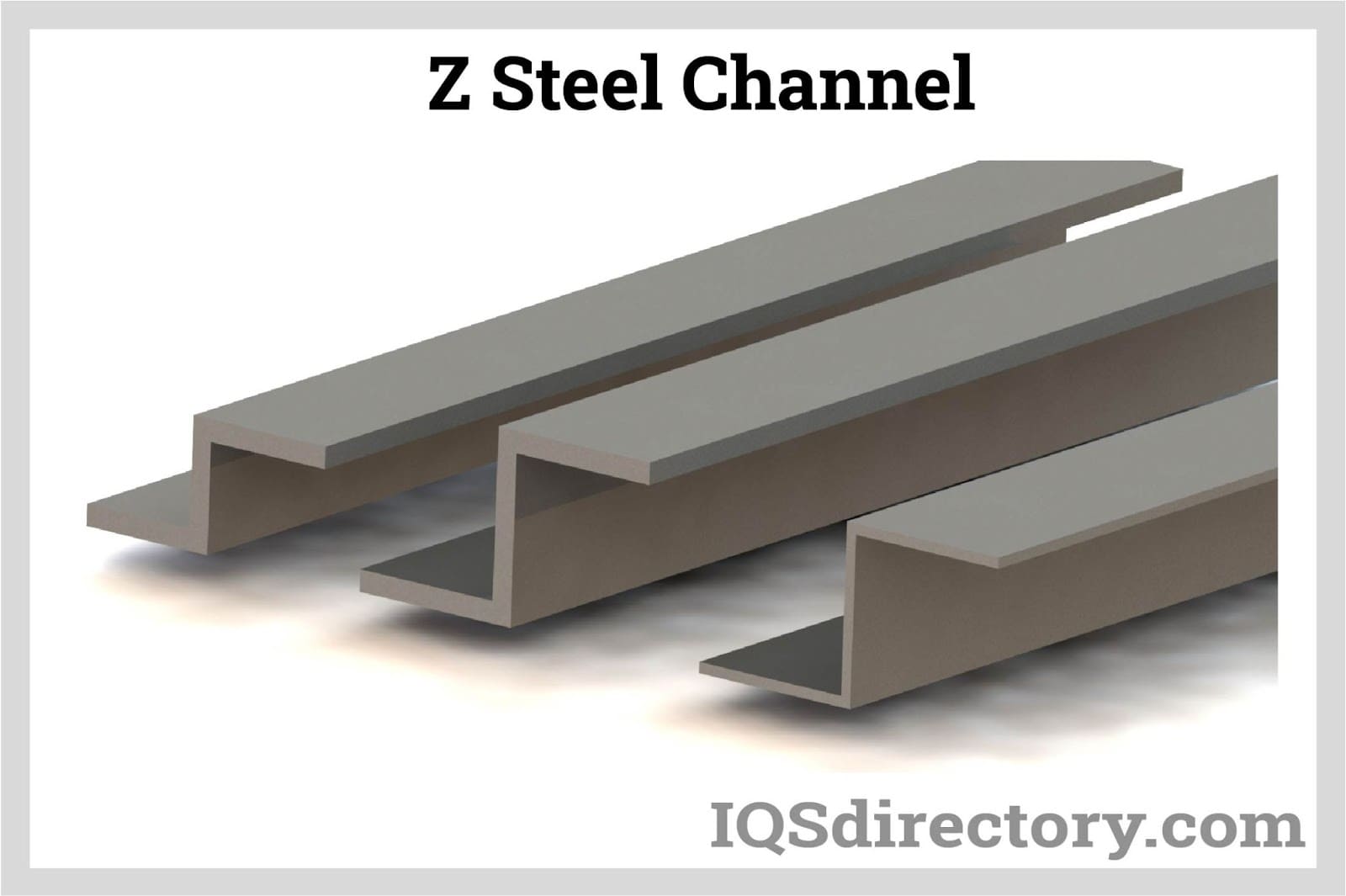

Z Steel Channels

Tooling is typically necessary when there are repeats at the top of each leg, except if dies with the correct dimensions exist. Z channels with a small web between the legs could need new dies, but they're less costly than dies for channels with longer webs. They are most typical in the metal and framing building sectors. Z channels can have inward flanges as well, but they are rarely seen.

Applications of Steel Channels

- Buildings with metal or wood frames can use steel channels to create sturdy frames for doors and windows. The channel slides across the walls in the door or window opening and comprises four sections with triangular joints. This is significantly more secure than wood frames and creates a level ground in the gap on which a door may be fixed.

- Steel channels are commonly used to frame commercial fire and basement doors that are below grade.

- Car frames are typically constructed using steel channels. The top frame rails are typically built of heavy-duty steel channels and operated from the front to the back of the automobile. Steel channels can be used to make radiator supports, braces, and other structural elements.

- Steel channels give a vehicle the proper strength and rigidity to avoid excessive bending while still providing enough movement to account for the engine's torque.

Choosing the Proper Steel Channel Supplier

To make sure you have the most productive outcome when purchasing steel channels from a steel channel supplier, it is important to compare at least 4 suppliers using our steel channel directory. Each steel channel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each steel channel company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple steel channel companies with the same form.

Cold Headed Parts

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services