M.P. Metal Products, Inc.

M.P. Metal Products, Inc.Request A Quote

Ixonia, WI | 920-261-9650M.P. Metal Products is an ISO 9001:2008 certified manufacturer of roll formed products. We have specialized in roll forming since 1965, and with 35 roll formers we can manufacture many different shapes including metal channels, trim, profiles, framing, and much more. An extensive stock of common shapes allows customers to find simple solutions to their roll forming requirements, but custom roll forming is our real specialty. Our impressive selection of manufacturing capabilities opens up the opportunity to tailor products for use in a variety of different industries. These roll forming products are customized for and utilized in industries like the medical, electrical, material handling, and automotive industries. Metals like copper, aluminum, and a variety of steels can all be shaped from sheets, strips, or coils in our roll forming processes. We can economically produce 5,000 lineal feet of shapes or more with existing tools, and if new tooling is required, the threshold for economical production is nearer to 30,000 lineal feet. In conjunction with versatile manufacturing, roll forming with M.P. Metal Products also has several other distinct advantages. The roll forming process simply requires sending the desired metal through rolls which continuously bends the metal until it reaches the final shape. There is no heating, and secondary operations can often be eliminated. Therefore, roll forming is a very efficient and economical alternative to other manufacturing processes. So whether you are in need of standard shapes or have more specialized applications in mind, roll forming with M.P. Metal Products provides the flexibility to satisfy your needs with quality and economical solutions.

Cold Headed Parts

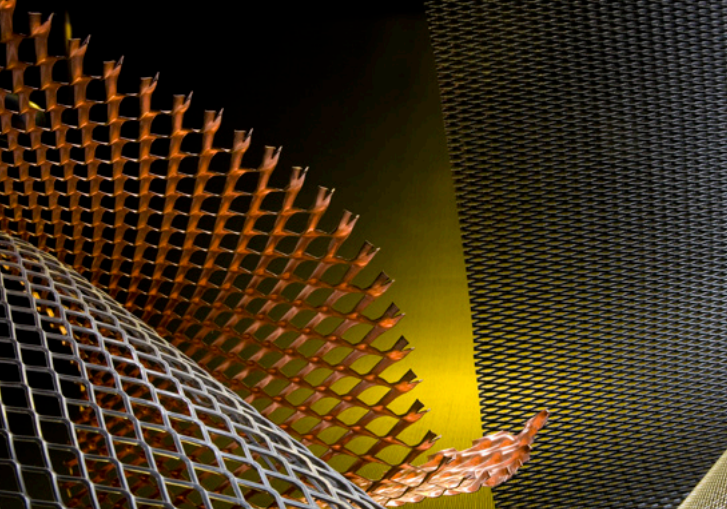

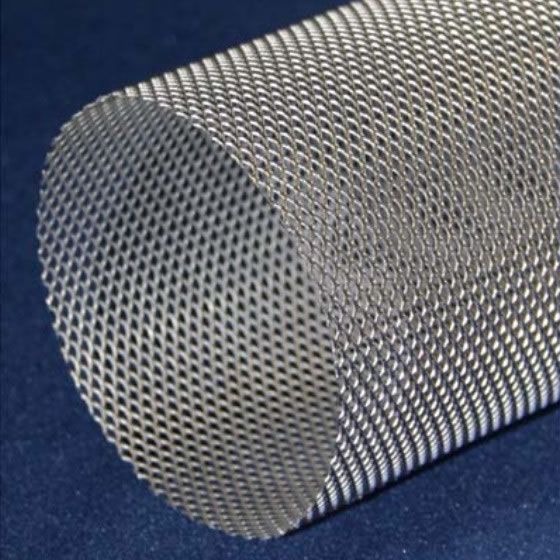

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services