A C-channel is a style of beam with two flanges rising from just one side of the flat surface and a large central part. The C-channel gets its name from the C shape it makes when it is turned on its side. For the greatest contact area and strength, a C-channel is typically utilized in locations where it can be fastened to a flat surface. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More C Channel Companies

What are C Channels?

To create an I-beam, C-channels are occasionally welded back to back. This unusual configuration can produce sturdy yet adaptable structural support.

How C Channels are Made

A C-channel is a style of beam with two flanges rising from just one side of the flat surface and a large central part. The C-channel gets its name from the C shape it makes when it is turned on its side.

For the greatest contact area and strength, a C-channel is typically utilized in locations where it can be fastened to a flat surface. To create an I-beam, C-channels are occasionally welded back to back. This unusual configuration can produce sturdy yet adaptable structural support.

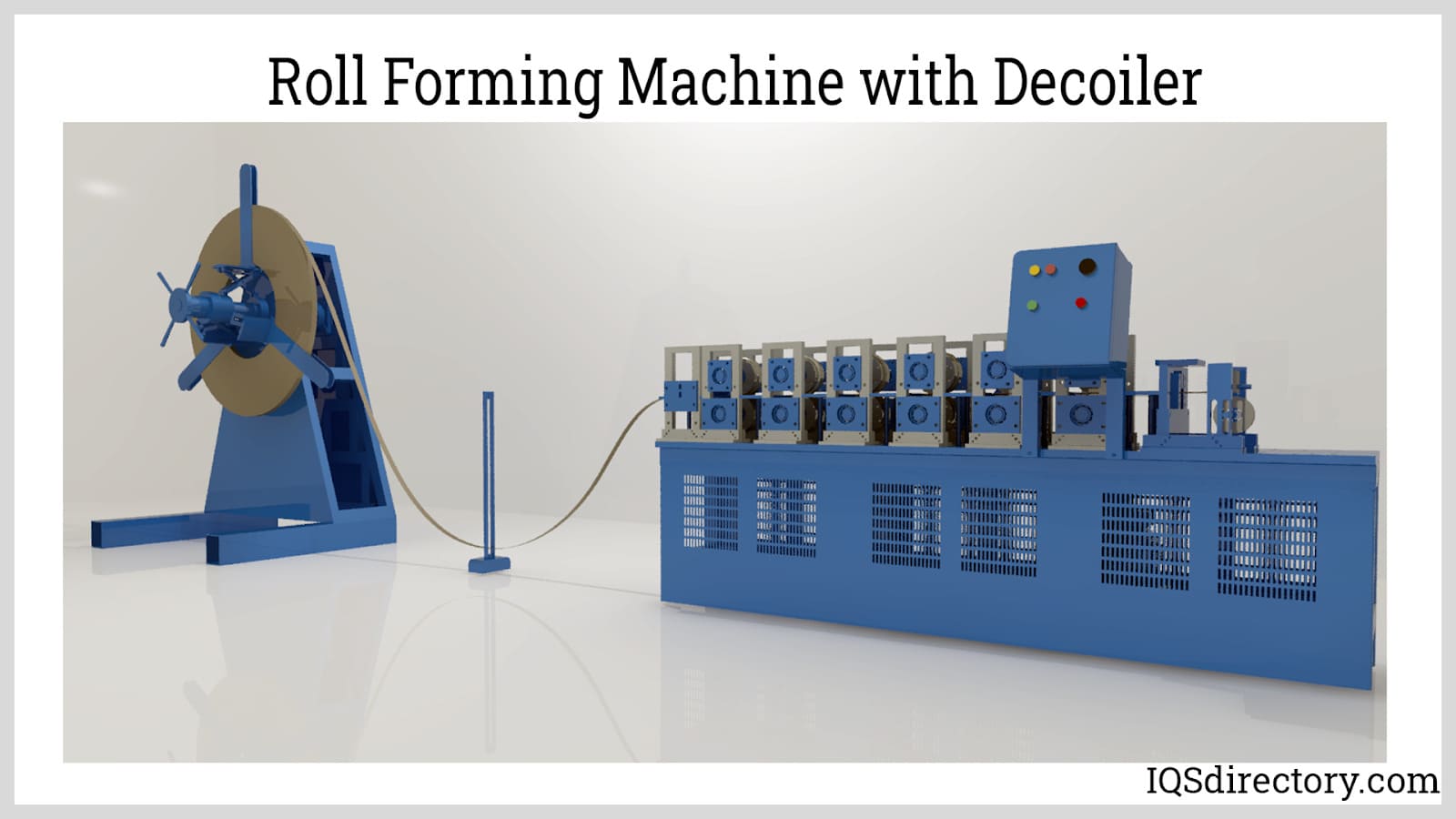

The roll forming machine contains a collection of precisely engineered dies installed in each stand to get ready for the roll forming process. These unique tools are created to perfectly suit the specifications of the metal channel that needs to be molded.

The roll-forming dies are separated into stations, each with a roller that gradually molds the metal sheet. The roll forming procedure starts after the CAD program has been downloaded and the dies have been positioned in the roll forming machine. The metal strip is pre-processed before entering an entry guide or table to ensure a square, straight entry into the first pass as it exits the uncoiler.

This step in the process is crucial to guarantee the quality of the finished product. Depending on the complexity of the metal channel, the required number of passes might range from only a few to thirty or more.

The start and finish of roll forming can be accomplished using a variety of techniques. In certain processes, straightening happens at the start, but in others, it happens at the conclusion. After the channel has been formed, whatever technique is utilized, the required length feeds out at the end, is cut to the precise measurements, and is then gathered on a table or pair of rollers.

Materials Used to Produce C Channels

Aluminum

Aluminum is the ideal material for creating metal channels due to its strength and versatility. Despite not having the same tensile strength as steel, it provides sufficient stability to be employed as a support in some situations.

Frame extensions, light poles, lighting fixtures, window and door frames, connectors, and the production of lightweight ladders all use aluminum channels. In addition, because of their good conductivity, metal channels made of aluminum are utilized as heat conductors and reflectors.

Steel

Steel is the material of choice for the production of metal channels due to its strength and durability. Construction companies employ its structural strength to create braces and frames for buildings and supports for diverse machines and heavy machinery.

Brass

Metal channels are created using a variety of brass grades. Architectural bronze, also known as Brass 385, is a particularly strong and durable variety of brass that has outstanding corrosion resistance and is simple to shape and mold. Brass 385 is used as support for decorative applications such as shelving and wall supports for exhibits and has a pleasing aesthetic look that polishes to a shiny finish. Brass can create exacting tolerances and lengths for any application.

Applications of C Channels

- The roof deck can be supported by rafters that extend from the eaves to the ridge and are made of various metals. Metal rafter channels have the same weight-bearing capacities as other materials while being lighter and smaller. Metal channels have a longer lifespan than wood because they are resistant to rot, deterioration, and the effects of dampness. Metal channels can serve as the primary or supplemental support for other materials while building roofs.

- Solar panels must be lightweight and strong enough to endure adverse weather. Metal channels are perfect in those circumstances since they satisfy both requirements. Metal channels provide the durability required to withstand the conditions where solar panels are mounted because of their high tensile strength. Metal channels' modest weight enables solar panel manufacturers to install their products in various climates and settings.

Choosing the Right C Channel Supplier

To make sure you have the most productive outcome when purchasing C-channels from a C-channel supplier, it is important to compare at least 4 suppliers using our C-channel directory. Each c-channel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the supplier for more information or request a quote. Review each C-channel business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple C-channel businesses with the same message.

Cold Headed Parts

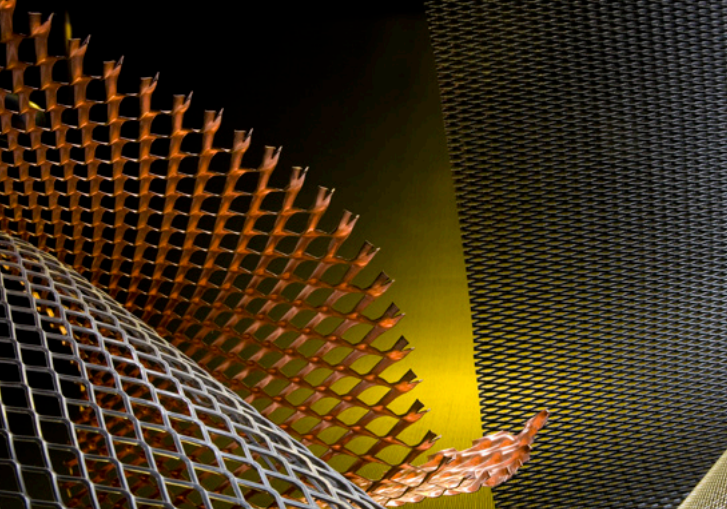

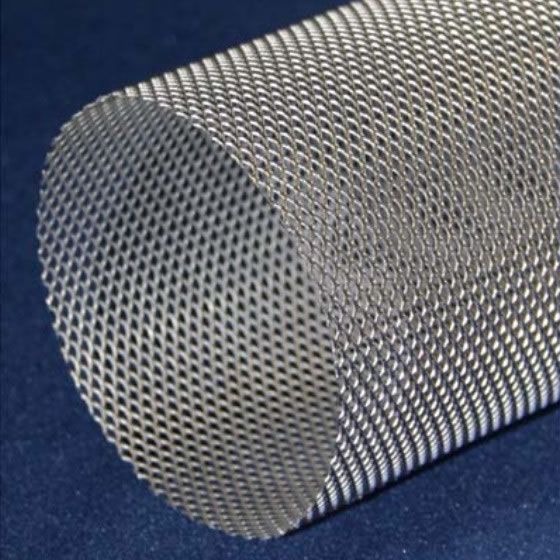

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services