United Roll Forming, Inc.

United Roll Forming, Inc.Request A Quote

Elkhart, IN | 800-998-5940https://www.unitedrollforming.org/

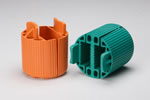

United Roll Forming has set itself apart in the roll forming industry, offering matchless customer service and expertise in design and manufacturing. Located in Elkhart, Indiana, we have been roll forming aluminum and steel for customers all over the world for over 50 years. With 3 production plants, over 50,000 square-feet of state-of-the-art roll forming equipment, and experienced operators, even the most complex shapes take form. Our dedicated engineers make it their mission to assist customers with all their projects big and small, matching custom parts or creating new prototypes from drawings. With a fully equipped machine shop at our disposal, United Roll Forming has the versatility to provide a wide variety of services and parts. We have our own tooling to provide customers with standard shapes in a variety of sizes, quantities, and types of metal, but with our tool and die shop we can provide custom machining as well. We specialize in the production of wheel well, outside trim, inside trim, and fender pieces. Our extensive bending services allow us to produce aluminum and steel wheel wells, outside and inside trim, roof bows, side walls, and seat tracks. Our in-house stock of almost every type of steel, galvanized, and aluminum square tubing also offers customers a quick turnaround. Roll forming with United Roll Forming is an excellent way for customers to obtain their parts more efficiently and with greater quality. Rolled formed parts can be made much faster which means the cost per piece is reduced, and sub-assembly and fabrication costs are eliminated as well. Furthermore, cold roll formed shapes have a superior surface finish with the absence of processing marks, and roll forming maintains the customers desired contours.

Cold Headed Parts

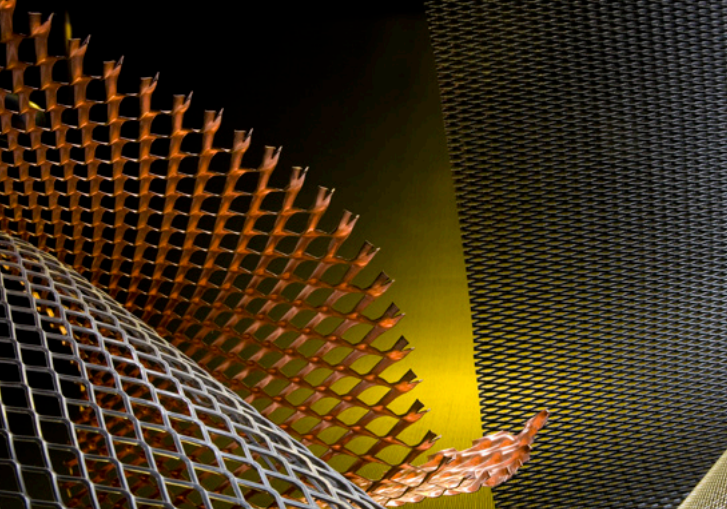

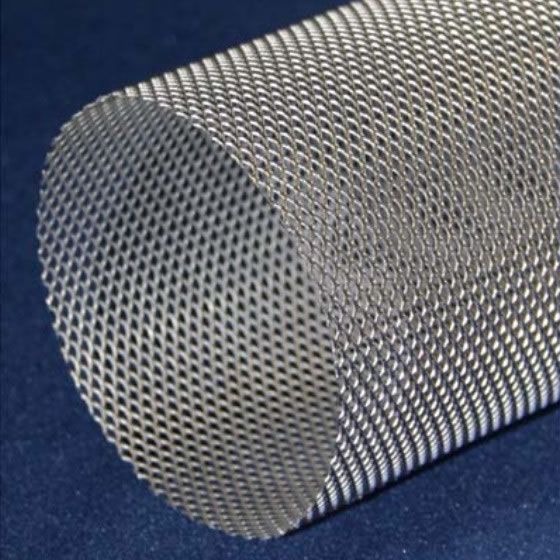

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services