A metal channel is a roll-formed metal sheet molded into a tube, a hat, J, or C shape for various industrial applications. Zinc, steel, brass, or aluminum are the kinds of metal used to make metal channels. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

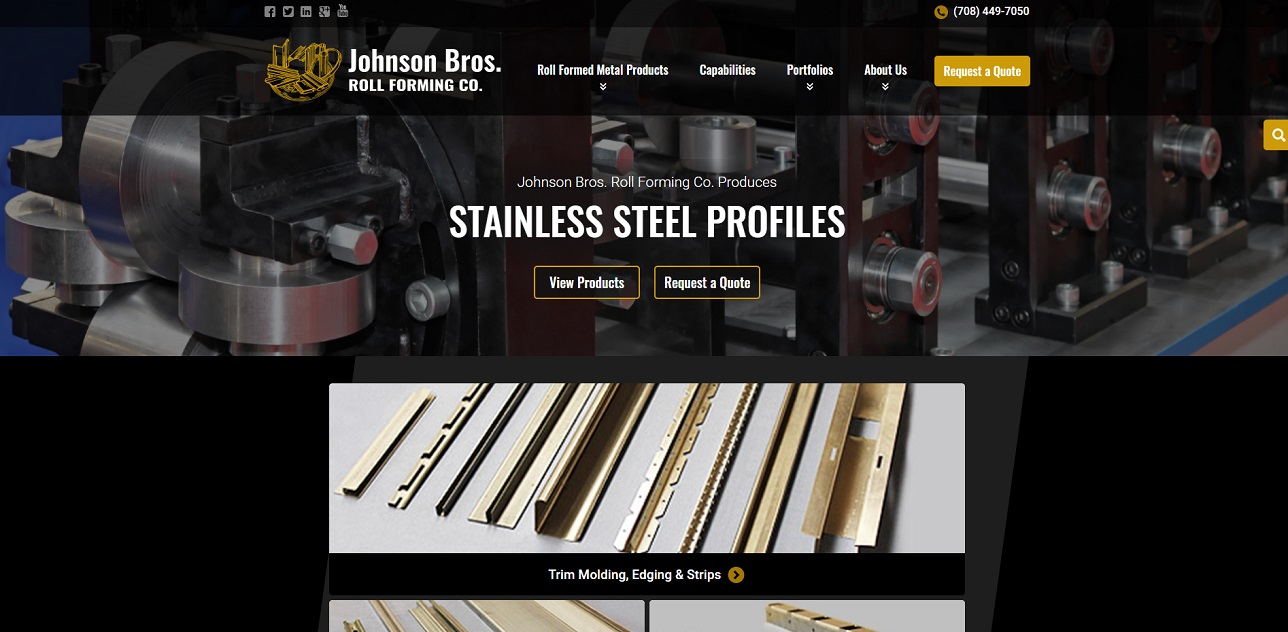

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

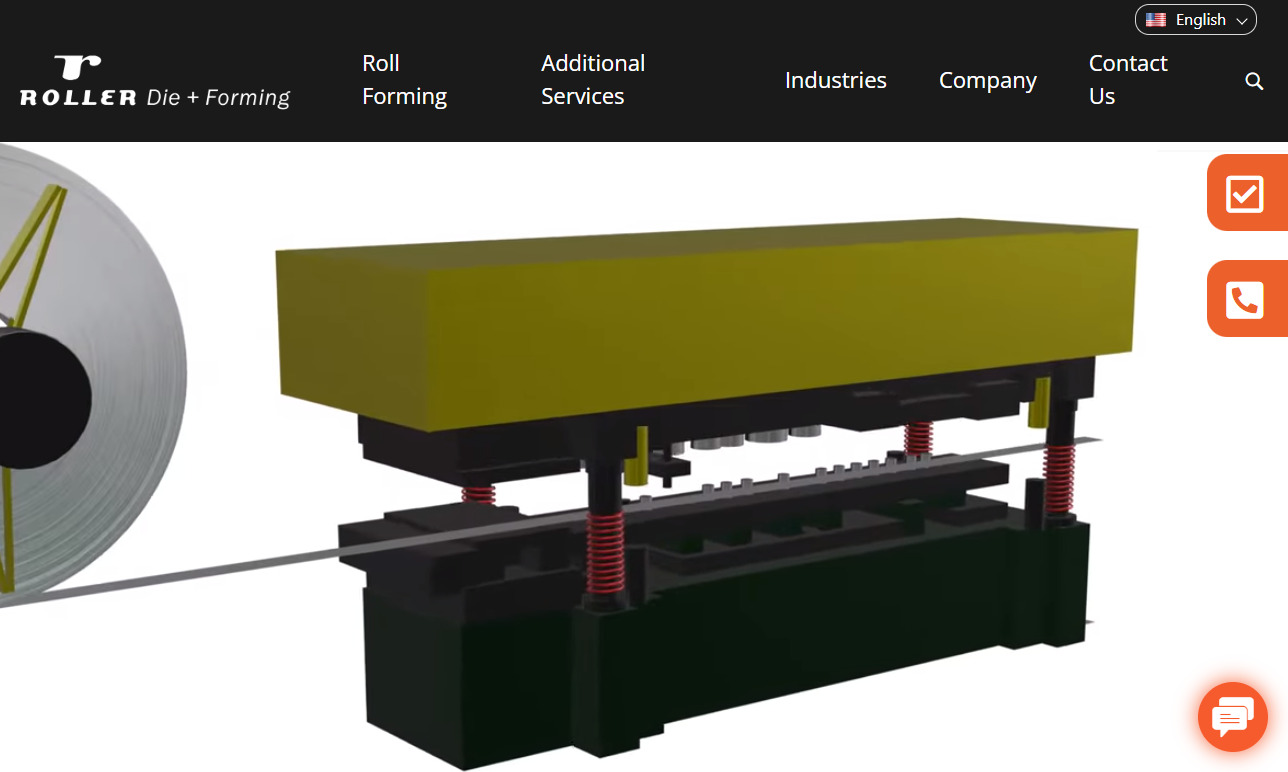

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Metal Channel Companies

Types of Metal Channels

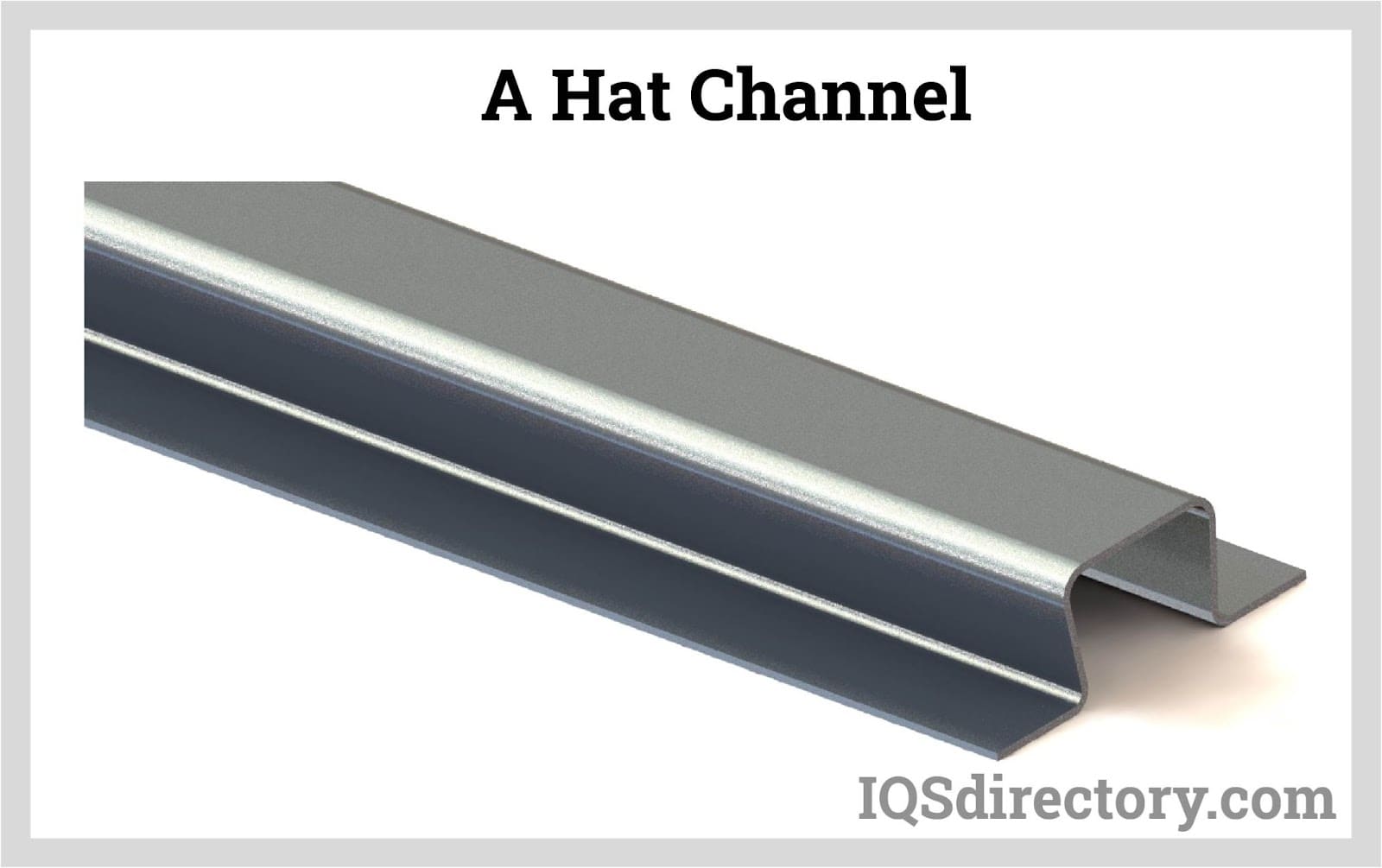

Hat Channels

The base of a hat channel has sides that are either straight up or angled.

C Channels

C channels are among the most popular metal channels and are frequently used in buildings.

J Channels

When a channel is built as a J channel, one of the sides is made wider than the other, creating a profile that looks like the letter J. Even though the basic J channel is available in various sizes and uses, other variants of J channels are designed to satisfy a variety of application requirements.

Metals Used In Metal Channels

Aluminum

Aluminum is the ideal material for manufacturing metal channels due to its strength and versatility. Even though it does not possess the same mechanical properties as steel, it gives sufficient stability to be used as a support in some situations. In addition, metal channels made of aluminum are utilized as thermal conductors and reflectors.

Uses of Metal Channels

Construction of Walls

Metal channels can be used to construct wall studs and bridges. These are typically located in the deepest layer of walls and offer vertical support for various wall materials, including plasterboard, paneling, cement, and similar materials. Metal studs are superior to wooden studs because of their increased durability. Because of this, they are perfect for usage even in rainy or high-moisture situations, which are unsuitable for maintaining wood studs. Steel channels are a sleek, room-saving form used for basic wall construction. When separating various regions of a room, they also offer transparent partitions.

Roofing

The rooftop of a building has a series of components called rafters. They are often installed as a part of a structure that includes ceilings, wall plates, battens, purlins, and joists. Roofing decking and other materials like corrugated sheets or solar panels cannot be supported without rafters. All joints that might not be extremely durable can be replaced by steel channels, either C- or U-shaped.

When the roof weight may pressure the ceiling, they provide superior support and enable more even weight distribution. Steel channels, when utilized as rafters, also offer sufficient defense against strong wind loads, keeping the building from separating and collapsing.

Automobile frames

Metal channels specially crafted and fashioned are made to provide specialized and distinctive purposes for various vehicles. Any vehicle's framework is essential for providing sturdy housing for the complete machinery and safeguarding various components. Metal channels can also go through additional hot-forming and metal fabrication to fit a vehicle body. The steel channels serve as both a connecting point for the vehicle's many parts and a safety framework for the driver. Metal channels designed specifically for automobiles can lessen the effects of small crashes on the operator and limit injuries.

Bridges

Different kinds of vehicles, including sedans, trailer trucks, 10-wheelers, and motorcycles, travel over bridge decks. Steel channels support maintaining all of the bridge's components intact so that the deck can support these structures. They can be found in the bridge's various trusses and other supporting structures. Metal channels provide superior endurance than other materials when utilized in load-bearing constructions like bridges. Metal bridges won't need a lot of maintenance or repairs because the material is durable. Additionally, they allow the bridge to operate longer, enhancing pedestrian and vehicular safety even after heavy use.

Door Frames

Metal channels are also employed as metal door frames in smaller applications, particularly when the door is constructed of timber or other flammable materials. By shielding the edges from harm and successfully lowering the rate of excessive wear, metal door frames also lengthen the life of the main door body. While not all kinds of metal channels are immune to corrosion, they can be covered using a process called galvanizing.

The steel's surface is metallurgically altered by the zinc coating that has been applied, making it resistant to various environmental factors. In addition, galvanized steel channels provide an additional line of defense to safeguard wooden structures because they are also vulnerable to termite and rotting damage.

Enclosures

Metals channels are another option for steel nets in a variety of enclosures. Metal channels, such as steel enclosures, are used in the agricultural sector to house cattle and other equipment. They are far more durable than metal nets and offer a less expensive option because they require less upkeep and repairs. In addition, steel channels can be used in various industries to create completely secure enclosures aside from agricultural enclosures. For instance, they can discourage trespassers from entering important areas like banks, power plants, and other business buildings.

Choosing the Proper Metal Channel Company

To make sure you have the most productive outcome when purchasing metal channels from a metal channel company, it is important to compare at least 5 to 6 companies using our metal channel directory. Each metal channel company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each metal channel company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple metal channel companies with the same message.

Cold Headed Parts

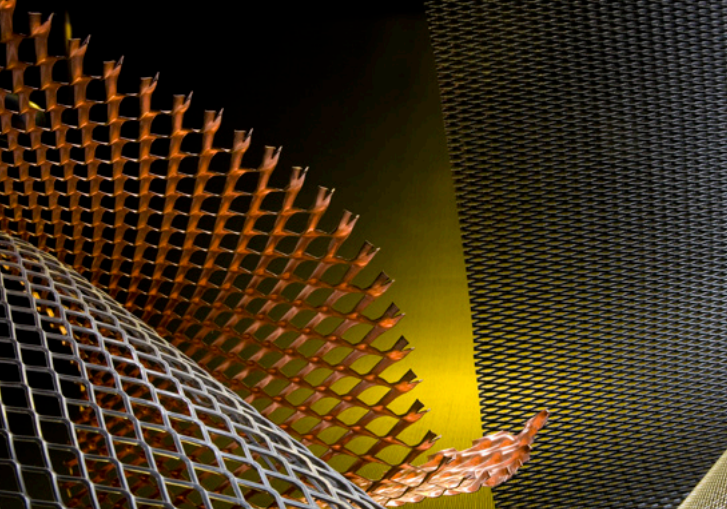

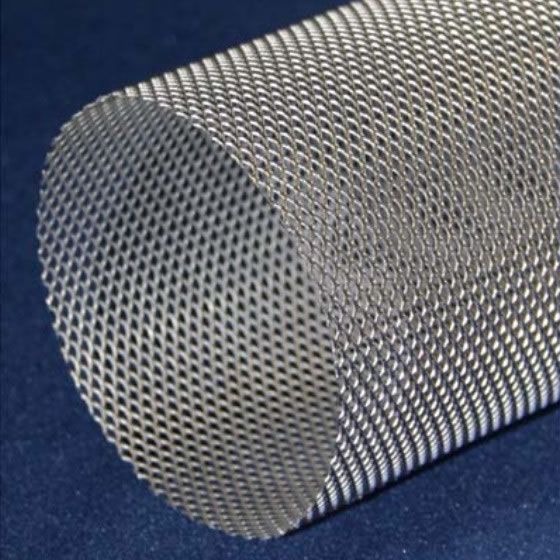

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services