Metal trim is a crucial element in architecture and construction. Not only does it enhance the aesthetics of a building or structure, but it also provides protection against environmental elements, adding durability and longevity to a project. In this article, we’ll discuss the process of creating metal trim, the variations in design and material, challenges of using metal trim, benefits of metal trim, and its various applications. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

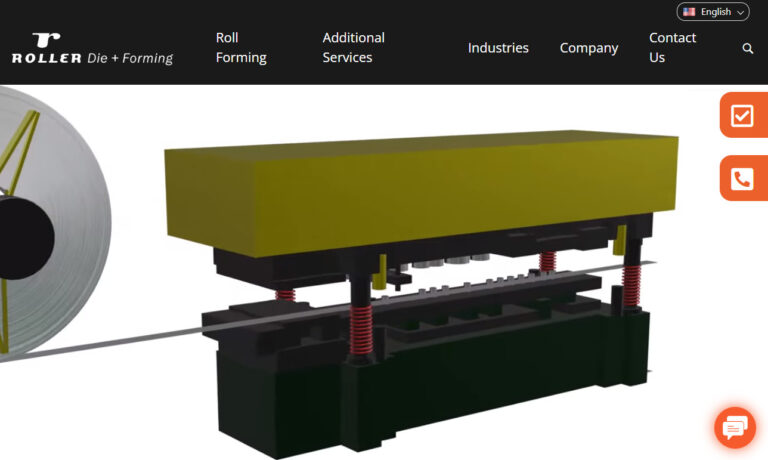

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Metal Trim Companies

The Process of Creating Metal Trim

The process of creating metal trim often involves roll forming, a process where a flat strip of metal is fed through a series of rollers, gradually forming the metal into the desired shape. The process of roll forming is highly customizable and allows for a wide range of shapes and sizes. Other factors that can affect the creation of metal trim include the type of metal being used, the thickness of the metal, and the desired finish.

Design and Material Variations of Metal Trim

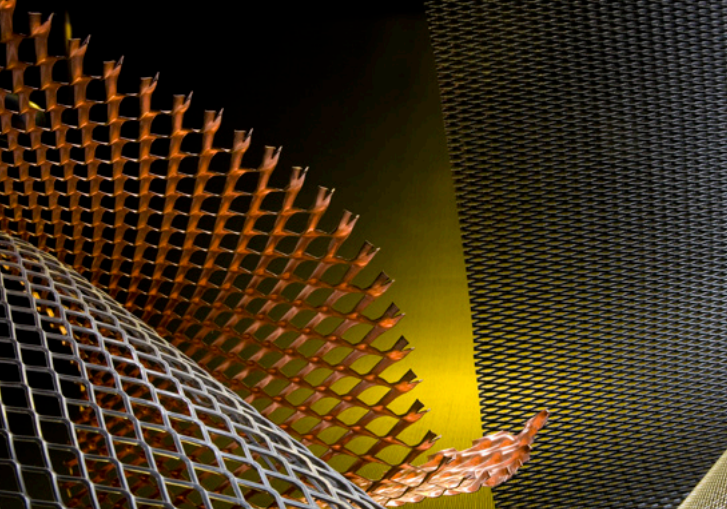

Design and material variations of metal trim are numerous, and each variation serves a unique function. The design of metal trim can range from simple, straight pieces to intricate designs that add visual interest to a building's exterior. The material used in metal trim can range from steel, aluminum, copper, or zinc, depending on the desired look and function. For example, copper is often used for its natural patina, while aluminum is lightweight and resistant to corrosion.

Challenges of Using Metal Trim

When using metal trim there are also some challenges to consider. One of the most common challenges in installing metal trim is ensuring that the trim fits securely and seamlessly with the rest of the structure. Proper installation is essential to ensure that the trim performs its function of protecting against environmental elements. Additionally, while metal trim is generally durable, some metals may require more maintenance than others to maintain their appearance.

Benefits of Using Metal Trim

Despite these challenges, there are many benefits to using metal trim. Metal trim adds a sleek, modern look to a building's exterior while also providing a layer of protection against the elements. Unlike other materials, metal trim is resistant to rot, warping, and pests, making it a cost-effective option in the long run. Additionally, metal trim is highly customizable, allowing for a unique look that sets a building apart from others.

Applications of Metal Trim

Metal trim can be used in a variety of applications, such as:

Roofing and Siding Applications

Metal trim is commonly used for roofing and siding applications. Metal trim serves as an important element in sealing and finishing the edges of roofs and siding panels. It also helps protect against the elements, such as wind and rain, and prevents water from seeping in between the panels. Metal trim for roofing and siding applications is typically made from aluminum, steel, or copper and is available in a range of finishes, including painted, anodized, and coated.

Baseboards

Metal trim can be used as a baseboard in both residential and commercial applications. Metal baseboards are a great alternative to wood because they don't rot, warp or deteriorate over time, making them a durable and cost-effective option. Metal baseboards are available in various styles and finishes, including brushed and polished metal, to complement any interior design.

Crown Molding

Metal trim can also be used as crown molding to enhance the aesthetics of a room. Metal crown molding is available in a variety of styles, including classic, modern, and art deco, and can add a touch of elegance and sophistication to any room. It is commonly made from aluminum, steel, or brass and can be painted or polished to suit any interior design.

Door Frames

Metal trim is often used for door frames because of its durability and resistance to wear and tear. Metal door frames can be made from aluminum or steel and are available in a variety of finishes, including powder-coated, painted, and anodized. They are also resistant to moisture and insects, making them ideal for use in high-traffic areas or areas with high humidity.

Window Frames

Metal trim is commonly used for window frames because of its durability and resistance to wear and tear. Metal window frames are typically made from aluminum or steel and are available in a range of finishes, including painted, powder-coated, and anodized. They provide excellent thermal insulation and are resistant to moisture and insects, making them ideal for use in high-traffic areas or areas with high humidity.

Stair Nosing

Metal trim is often used as stair nosing in both commercial and residential applications. Stair nosing is a protective element that helps prevent slips and falls on stairs. Metal stair nosing is durable and resistant to wear and tear and is available in a range of finishes, including brushed and polished metal.

Furniture Trim

Metal trim is also used as furniture trim to add a decorative touch to cabinets, tables, and chairs. Metal furniture trim is available in a range of styles, including modern, traditional, and art deco, and is typically made from aluminum, brass, or stainless steel. It is also available in various finishes, including polished, brushed, and textured.

Choosing the Right Metal Trim Supplier

To ensure you have the most productive outcome when purchasing metal trim from a metal trim supplier, it is important to compare several companies using our directory of metal trim suppliers. Each metal trim supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each metal trim business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple metal trim companies with the same form.

Cold Headed Parts

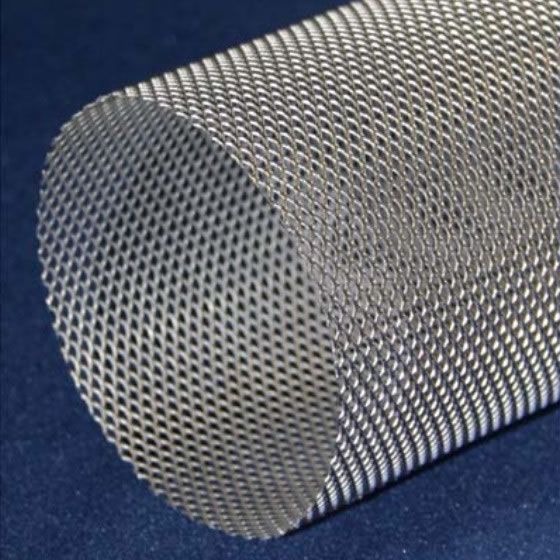

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services