Premier Products of Racine, Inc.

Premier Products of Racine, Inc.Request A Quote

Racine, WI | 262-633-2200https://www.customrollform.com

Premier Products of Racine, Inc Specializes in Custom Roll-Forming, Custom Metal Stamping, and Custom Sheet Metal Fabrication, welding, riveting, and assembly services. Since 1999 we have been servicing the office furniture, barbecue, appliance, solar technology, telecommunications, appliance, and tanker industries. We offer TIG, MIG, and wire welding. Premier Products we offer complete custom roll-forming services, that include measurements 0.010" to 3/16" thick, and up to 12 inches wide. Premier Products has an approximately 0.003" precision cross-sectional tolerance, and an angular dimensional tolerances of ± 0.25°. We have eight roll forming mills that allow us to manufacture parts that meet these specifications. We have the capability to fabricating with aluminum, copper, titanium, and all types of steel. cleaning, cut-off, and embossing are some of the in-process capabilities that our roll-forming fabrication offers. Premier Products of Racine has a 100-400 ton presses that run from 50-140 strokes a minute. Our presses can fabricate parts that are 0.010" to 3/16" thick, with a tolerance of ±.002". Our presses have the capability of various stamping methods; coin, continuous, progressive, perforated metal, and compound die. Premier Products offers the finishes of chrome plated, plating, E-coating, black oxide coating, and anodized. We have the capability of stamping copper, galvanized steel, titanium, and galvalume. Here at Premier Products we offer many Custom Metal Fabrication services, that include bending, forming, punching, welding, assembly, edge conditioning, and shearing. Some of the finishing options that are offered are plating, powder coating, cosmetic brushed finishes, pre-painted, painting, and anodizing. We fabricate parts that meet the ANSI, ASTM, DOT, and Mil-Spec standards. Premier Products of Racine works with carbon steel, copper, aluminum, cold rolled steel, hot rolled steel, and titanium.

Cold Headed Parts

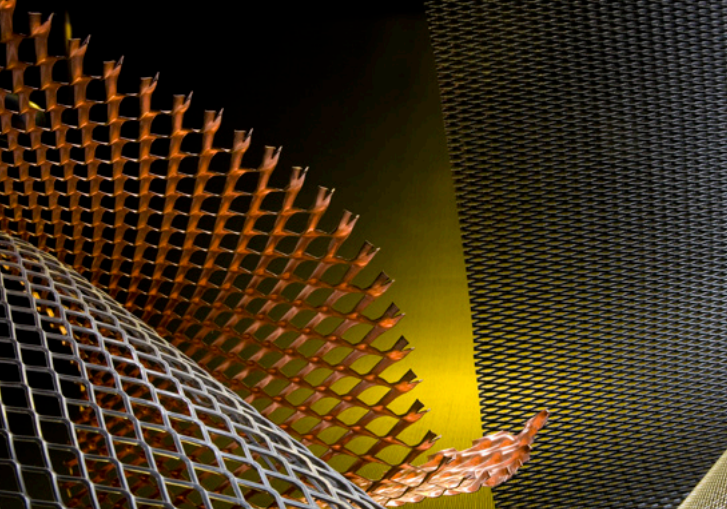

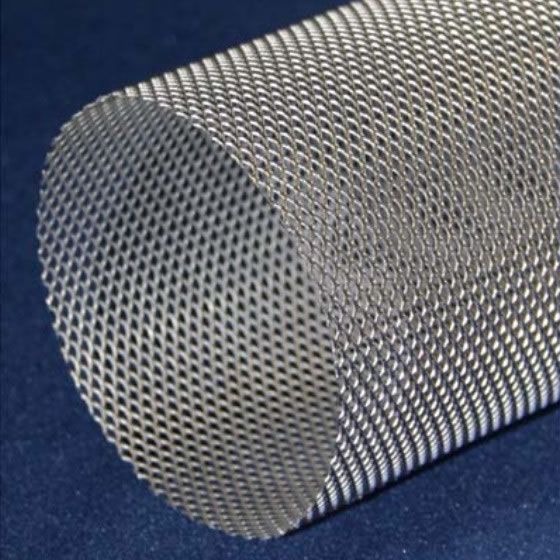

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

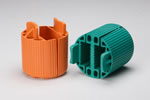

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services