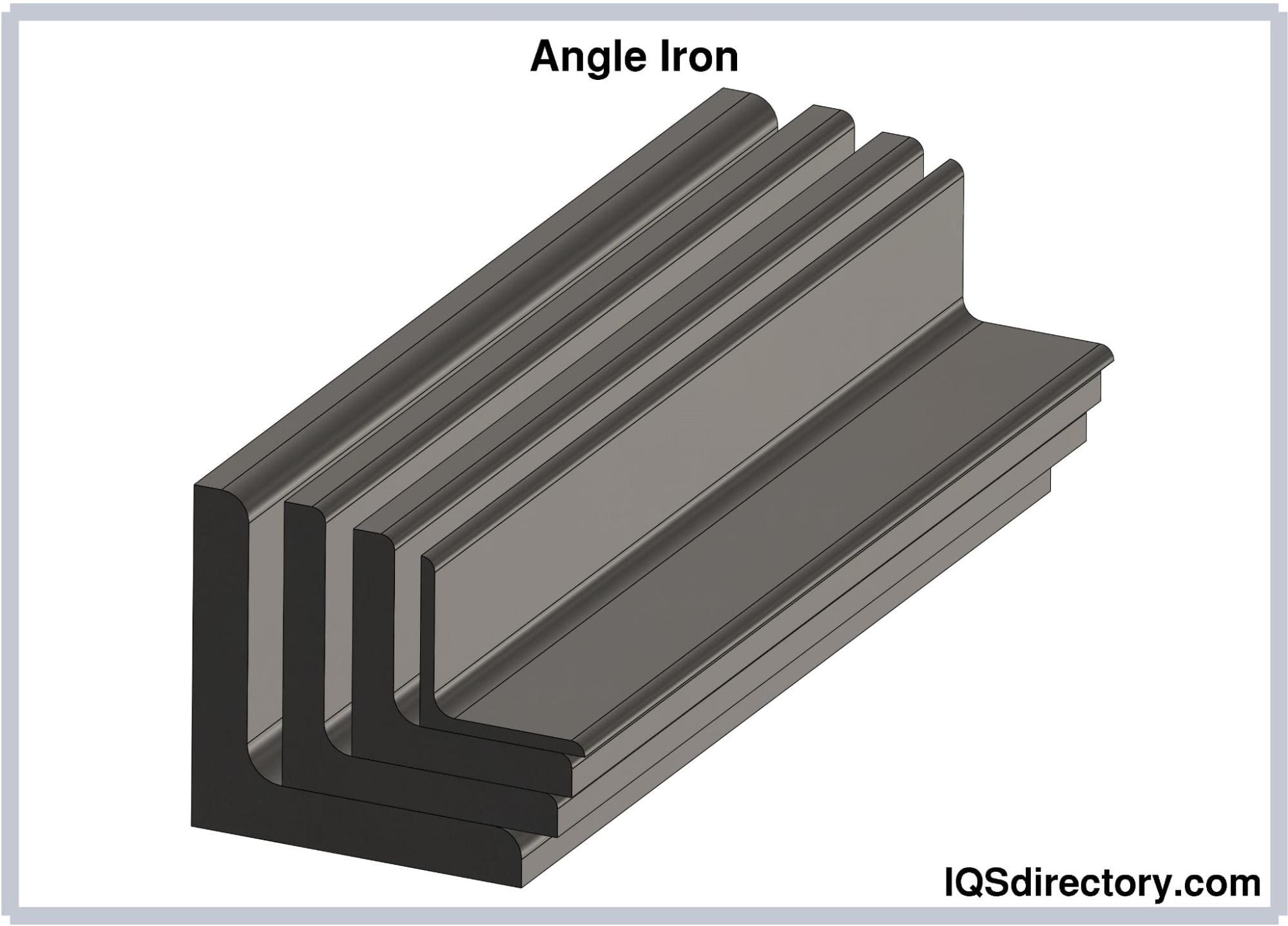

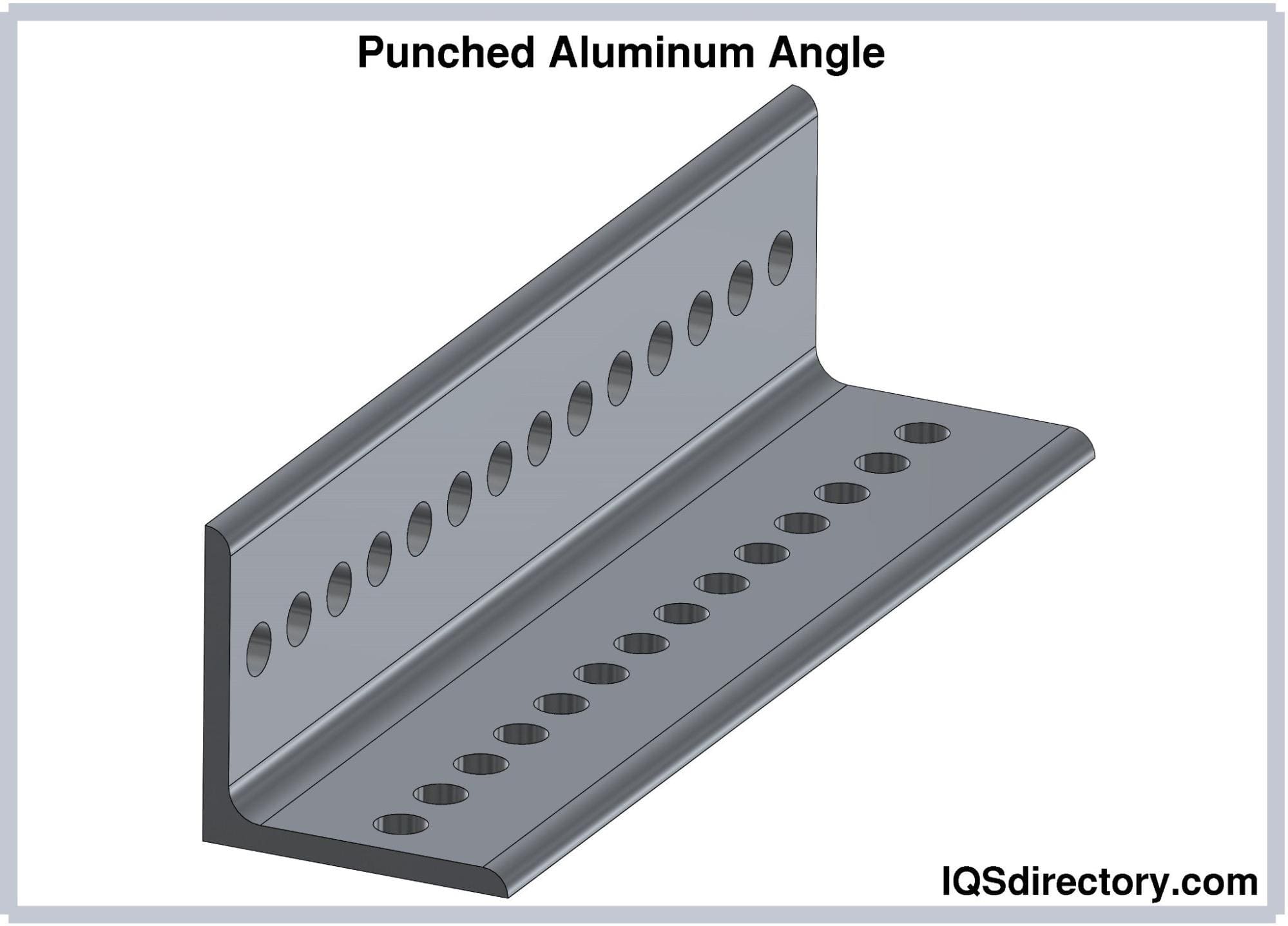

An L-shaped piece of long, rectangular sheet metal or flat bar folded at a 90-degree angle along its long axis is generally known as angle iron. Angle iron is frequently used to frame or construct various furniture items, supporting frameworks, walls, or shelves. Angle iron provides additional support where two materials come together at a straight angle. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Angle Iron Companies

Regardless of the force, it may support the weight from the top or the side. No matter how long, an angle iron may not feel robust enough when held in hands for that use. Angle irons can provide additional support independent of the weight applied, despite what their size and weight might suggest. Angle iron used for structural purposes comes in a wide range of diameters.

As a relic from older times when they were almost exclusively constructed of iron, the term "angle iron" is used to describe the shape of the item rather than the material from which it is made. Angle iron, made of steel and aluminum, is still the most used today, but other metals like brass are occasionally employed. Angle iron is used to build the fundamental furniture framework, such as chairs, beds, and tables, and other materials are used to finish the piece. This material offers durability and steadiness to resist practically any application.

Angle Iron Types

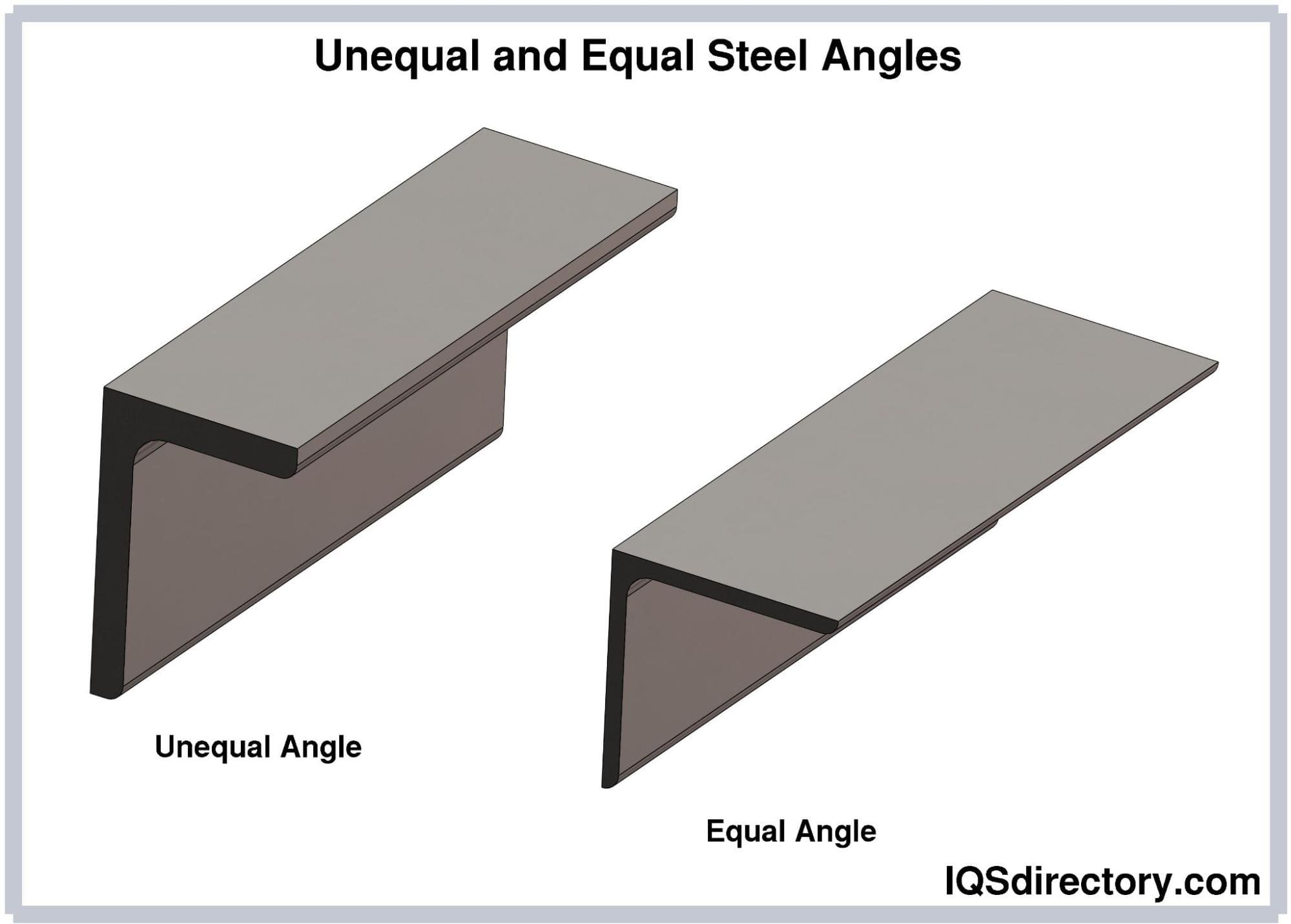

Steel Angles

An L-shaped metal called a steel angle is made from several kinds of steel. Because of its tremendous strength, it provides numerous advantages for architectural projects. In addition, it can be applied to many structural purposes and will provide additional strength to bear the weight of other materials placed on it.

Rarely, if ever, are steel angles used decoratively. For aesthetic reasons, they are typically too thick to be shown. However, steel is a more forgiving material when it comes to welding. Steel angles are ideal for welding because of their malleability, particularly in construction applications.

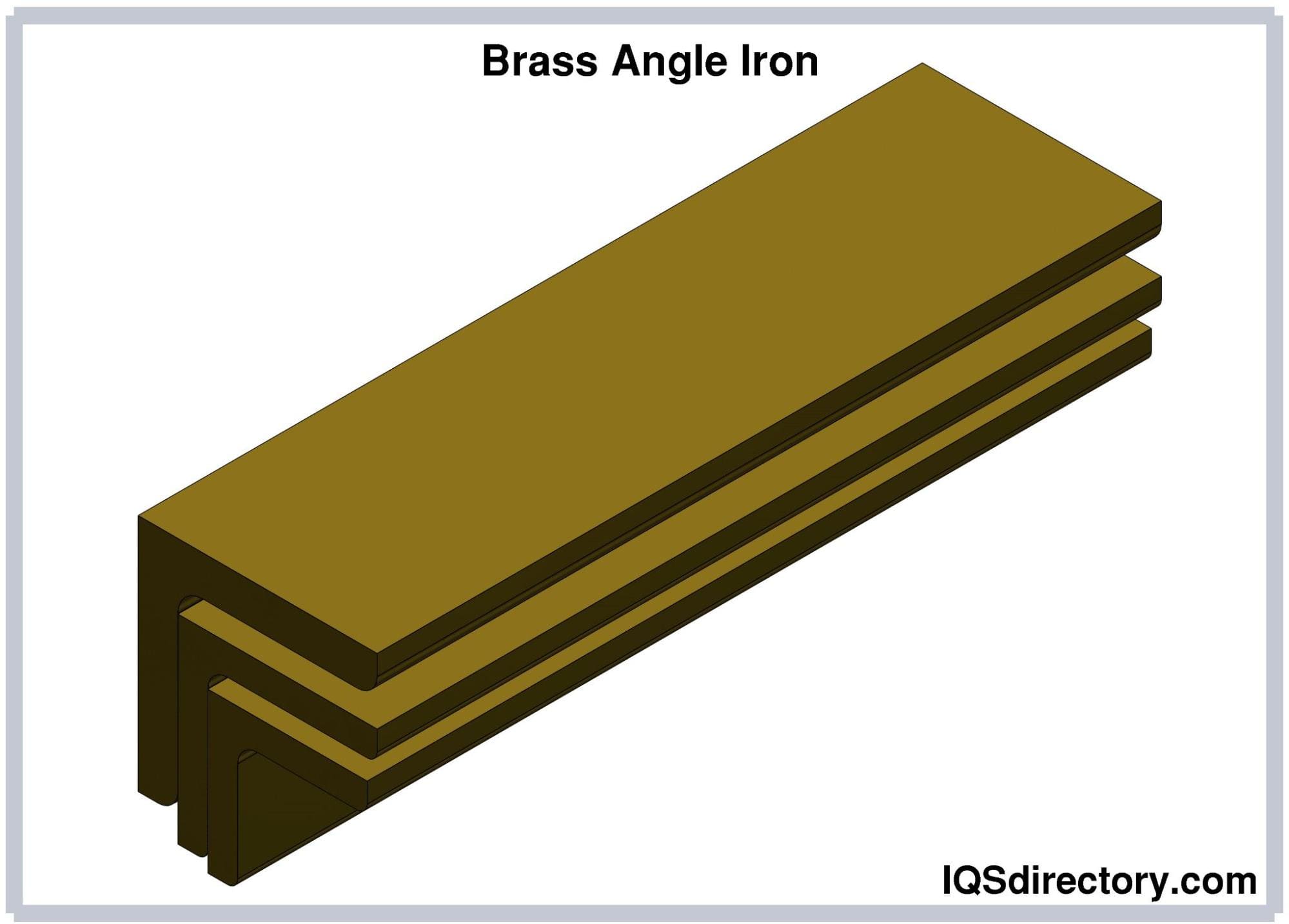

Brass Angles

A brass angle is one of the most useful metalworking tools, which has many uses in manufacturing, farming, and building operations. Angle brass bars are practical and distinctive, appropriate for various construction and maintenance tasks. In addition, they are frequently used for farming, fencing, and other urban operations. Equal angle brass is available from manufacturers in various sizes and thicknesses, as well as in unequal angles for more specialized uses.

Aluminum Angles

While steel and aluminum angles are both rectangular, there are distinctions between the two materials that must be considered. This corrosion-resistant, lightweight choice is sometimes referred to as a structural aluminum angle. It has many structural uses and can be used inside radius corners. Because the aluminum angle is so simple to weld, it is a fantastic material that will be an excellent choice for many future applications.

First off, aluminum can be welded, but it requires careful technique. This caution is because aluminum is easier to cut through and burn through, offering far more opportunity for error. However, steel is far more susceptible to rust than aluminum.

How Angle Iron is Used

There is a fairly large list of things that angle irons, or L angles, can be used for, including bed frames, kid's toys, chairs, skyscrapers, storage containers, and more.

- Work With Masonry: The door or window frame needs to be safeguarded from being crushed while building a wall out of bricks or blocks because they were not made to support that much weight. A long L angle can be added in both situations to support and shield the openings. A block wall's addition of shelving is equally true in this regard. A secure installation can be achieved by fastening an angle iron beneath the shelf.

- Shelving: L angles are not only used in masonry structures for shelves. They can be applied to drywall or wood walls of any kind. Screw anchors are required to secure the shelf and L iron, the same as in masonry. Angle iron can be used to hold a fireplace's mantel very firmly.

- Bed Frames: Metal bed frames use bed frame L angles to support a mattress' weight. Slats are used in wooden beds instead of metal ones to support the mattress. However, the slats might not be strong enough to support the weight of modern foam mattresses, which could cause the mattress to fall through the frame. So instead, L angles fastened to the sideboards and slats of the bed might strengthen it.

- DIY Initiatives: Angle irons can be used around the house for various repairs, such as when a chair leg separates from the seat, when a support on a deck collapses under the weight of furniture or a grill, or when building a gazebo in the backyard. When performing minor repairs, homeowners prefer to use the smaller L angles.

- Construction: Initial building structure blueprints include angle irons or L angles, which are utilized in construction but are much larger than those used for home projects. Depending on how they are required, they have various purposes. They provide support for some types of columns and beams used in the construction of buildings. Under vertical buildings like mobile homes and broadcast towers, they provide the tower with additional resistance and resilience in windy or other adverse weather conditions.

Choosing the Proper Angle Iron Manufacturer

To make sure you have the most positive outcome when purchasing an angle iron from an angle iron manufacturer, it is important to compare at least 4 to 5 companies using our list of angle iron manufacturers. Each angle iron manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each angle iron business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple angle iron businesses with the same quote.

Cold Headed Parts

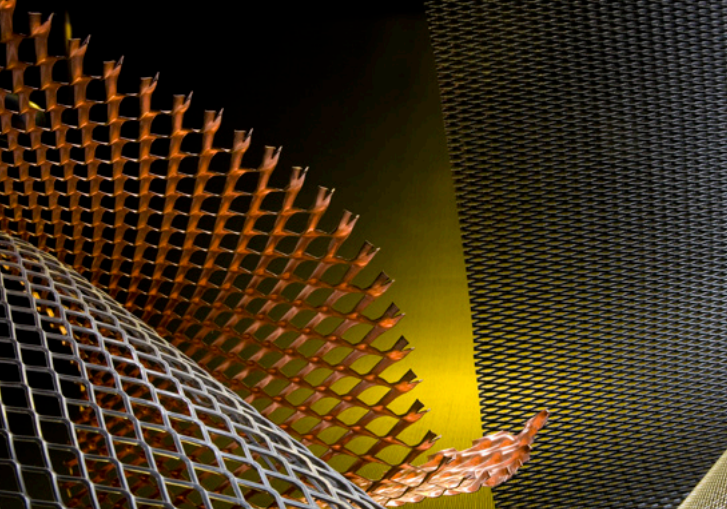

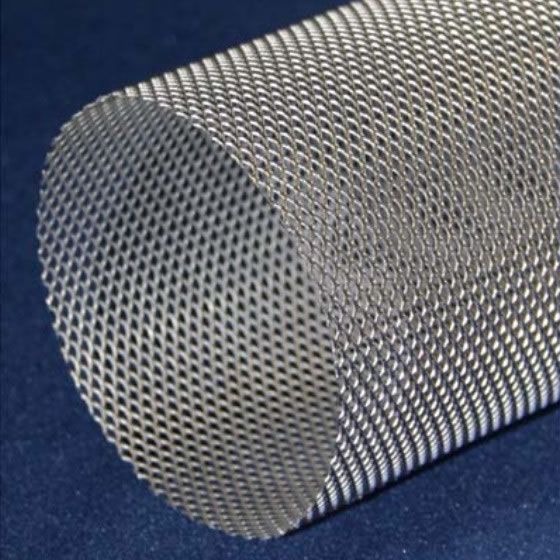

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

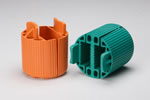

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services