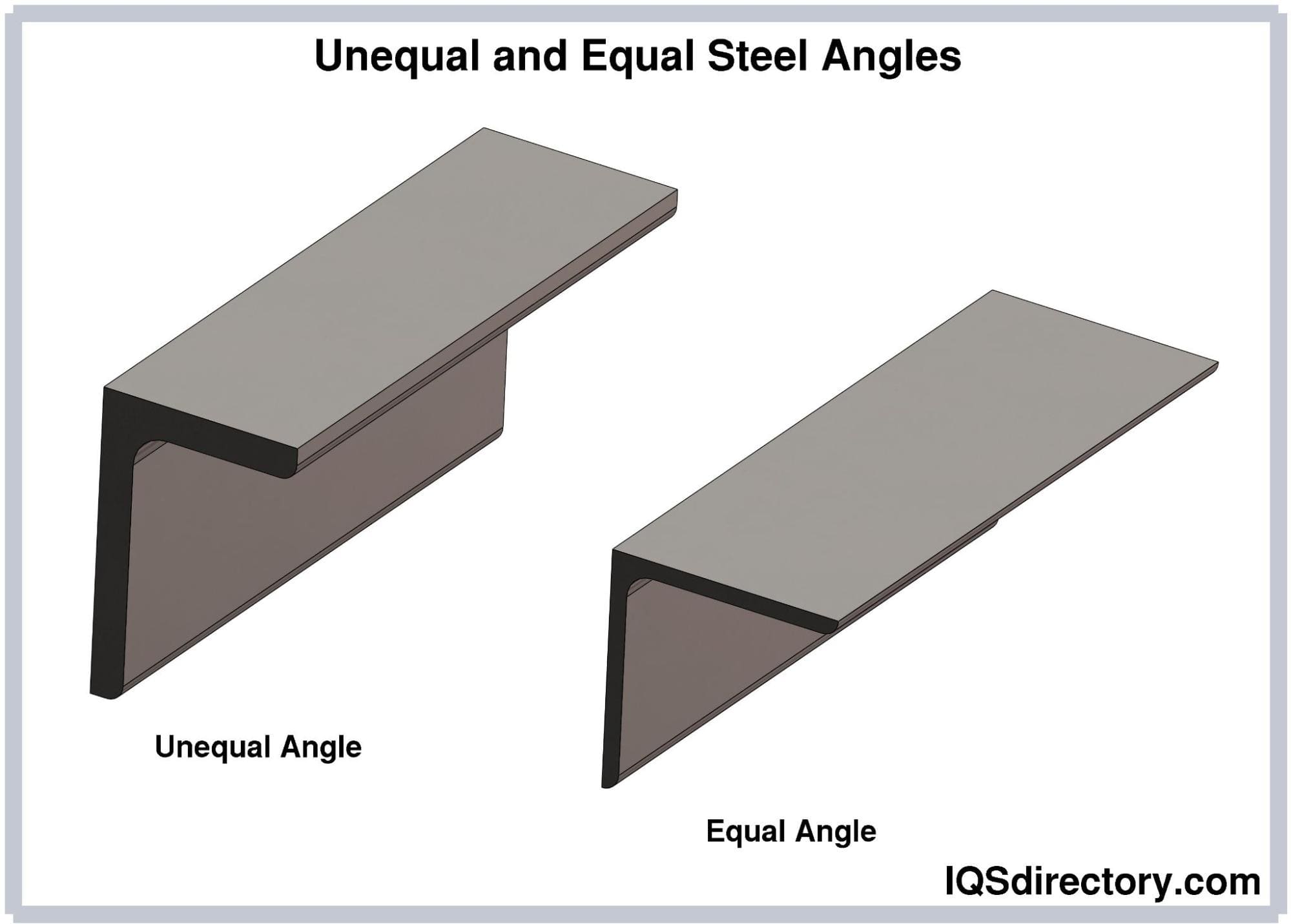

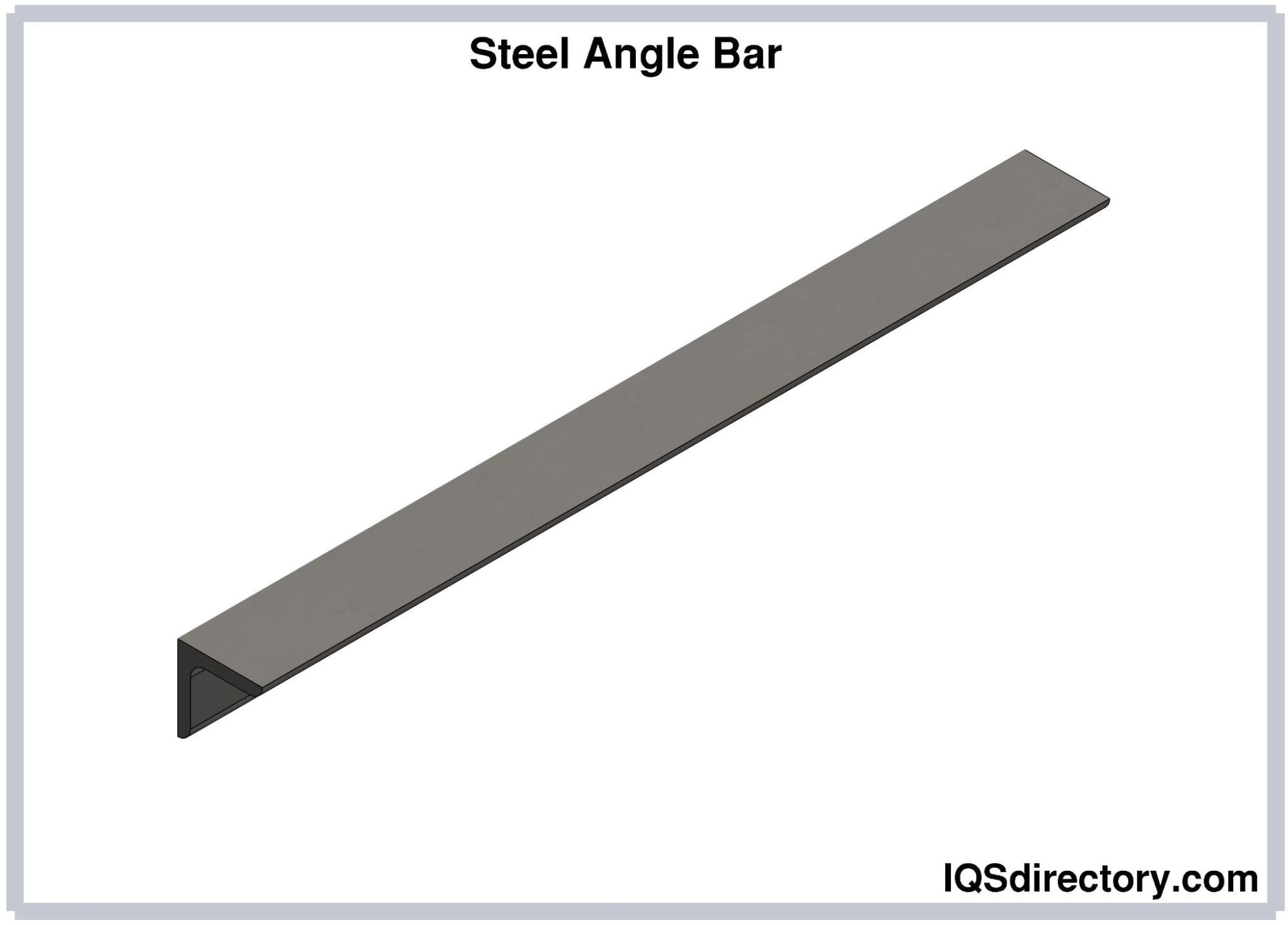

In essence, hot-rolled carbon steel or high strength low alloy steel is used to create a steel angle, also known as an angle iron or a steel angle bar. It features an L-shaped part with two legs that might be equal or uneven at a 90-degree angle. Angles made of structural steel come in various sizes to accommodate various needs. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

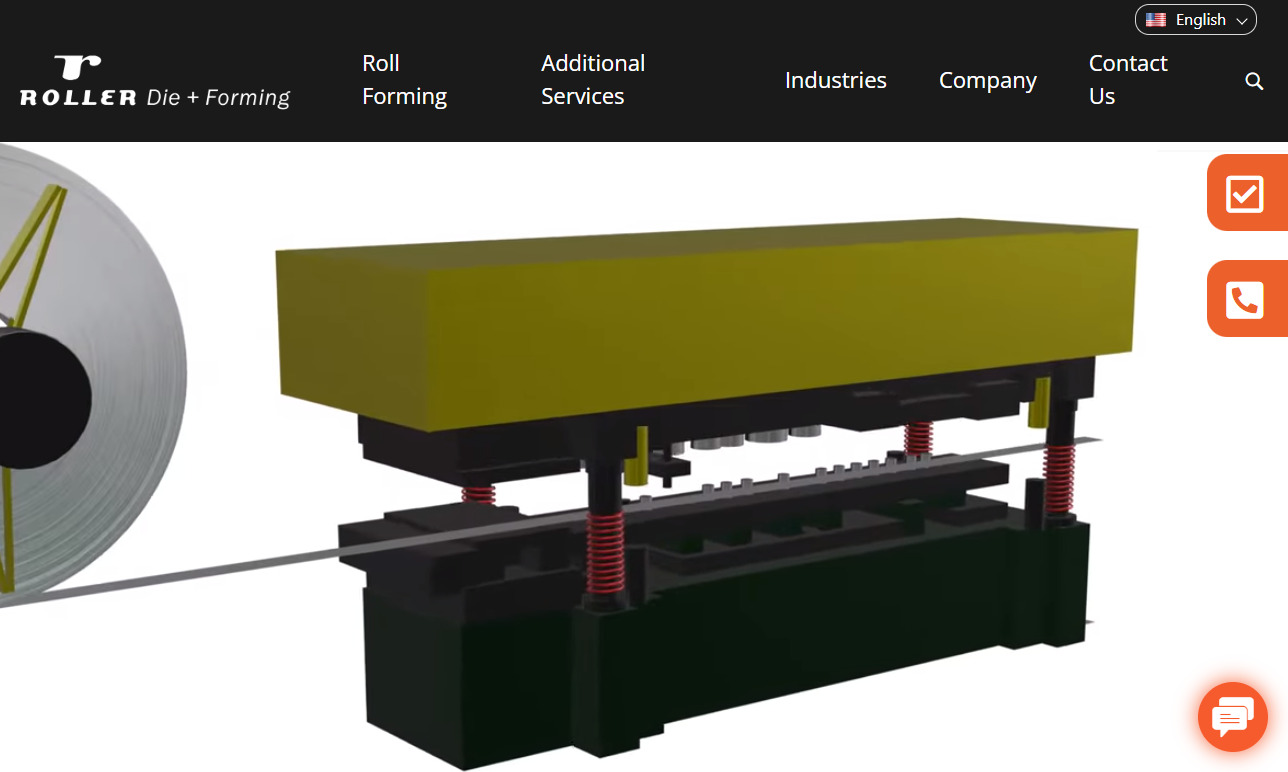

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Steel Angle Companies

The most common and fundamental roll-formed steel type is steel angles, which are the building blocks of steel manufacture. A steel angle is frequently used in building and design and can be used in various ways. For example, steel angles are frequently used in framing, brackets, and reinforcements across various sectors. They are particularly adaptable since they can usually be trimmed to size.

Steel Angle Sizes

Angles can also exist in versions that are equal or unequal. So said, equal angles have equal-length legs, but unequal angles have different-length legs. One choice may be more beneficial or practical depending on the project and dimensions requirements. For example, steel angles can have thicknesses ranging from 1/8" to 1-1/8" and leg sizes ranging from 1/2" to 8". Since the two leg dimensions and the thickness are the only information included in the standard size format for steel angles, reading it is relatively easy. For instance, an equal angle with legs of 4 inches and a thickness of 1/8 inches is 4" x 2" x 1/8.”

Application of Steel Angles

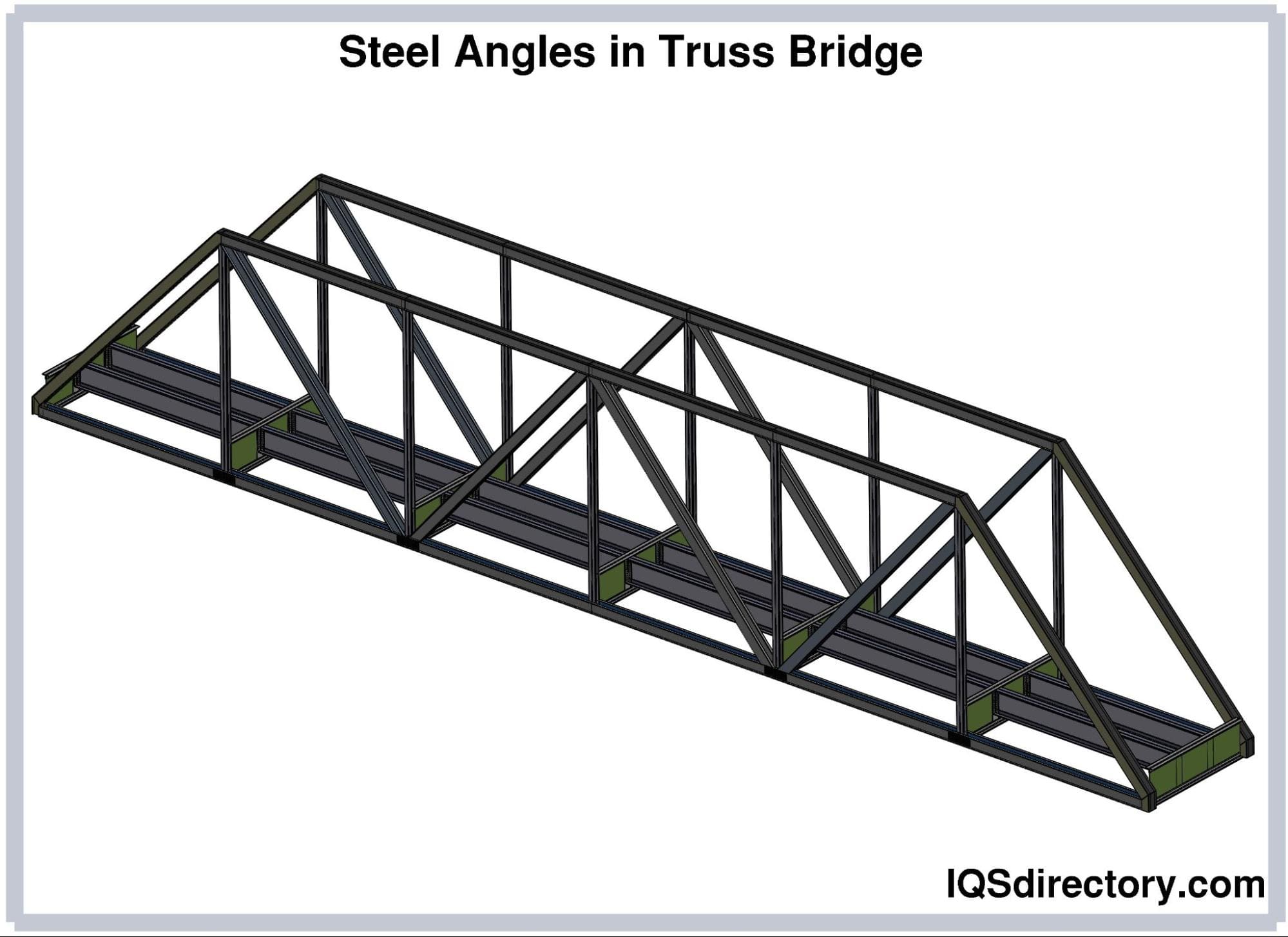

Bridgeways

Any component of a bridge may be made out of steel angles. The angles for the deck can strengthen the concrete and reduce the number of materials that builders must handle. In addition, steel angles are utilized in bridge parts, including girders, bearings, and arches or pedestrian pathways. Using steel angles without additional coating or protection is uncommon in a given building.

As a result, most steel angles commonly are powder coated or galvanized. Powder coating is a surface finish of electrostatic-spray deposited (ESD) resins. The galvanization process, meanwhile, forms a corrosion-resistant layer on the material. As a result, steel angles with a protective coating boost the material's longevity.

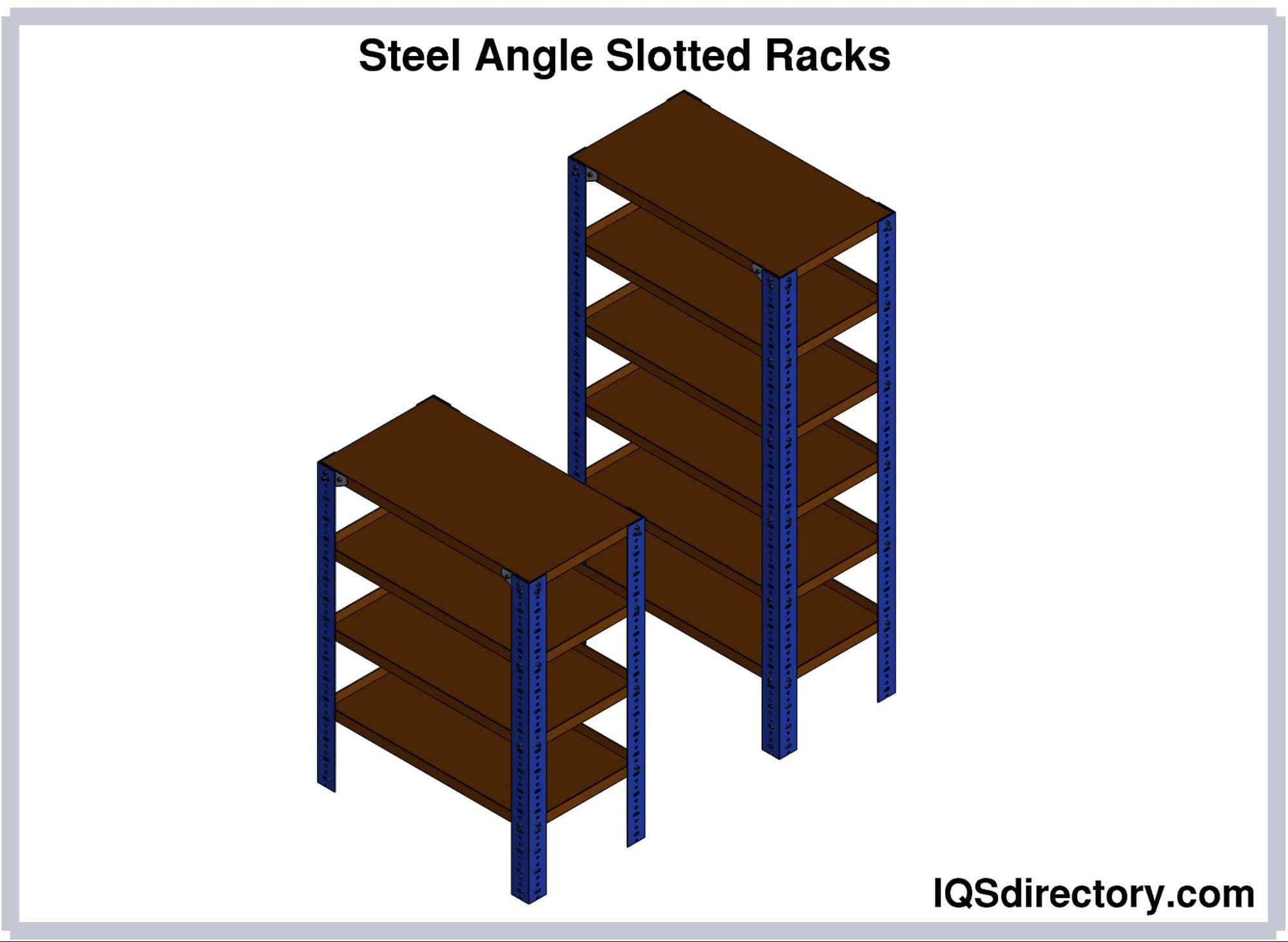

Warehouses

Steel angles can be used to support the roof of a building, build a mezzanine system, or serve as the framework for a warehouse. Steel angles are capable of supporting the raised flooring needs of mezzanines. These items can withstand a range of weights and impacts caused by the machinery and storage units utilized in the warehouse.

This strength and impact resistance are true regardless of the kind of mezzanine, whether it is freestanding, rack-supported, attached to columns, or shelving-supported. Steel angles are vital for ceiling or roofing construction in low-cost warehouses. The network of rafters that shields the warehouse from varying wind loads can be completed by connecting steel angles with various steel accessories, such as flat bars, rods, couplings, purlins, and fittings.

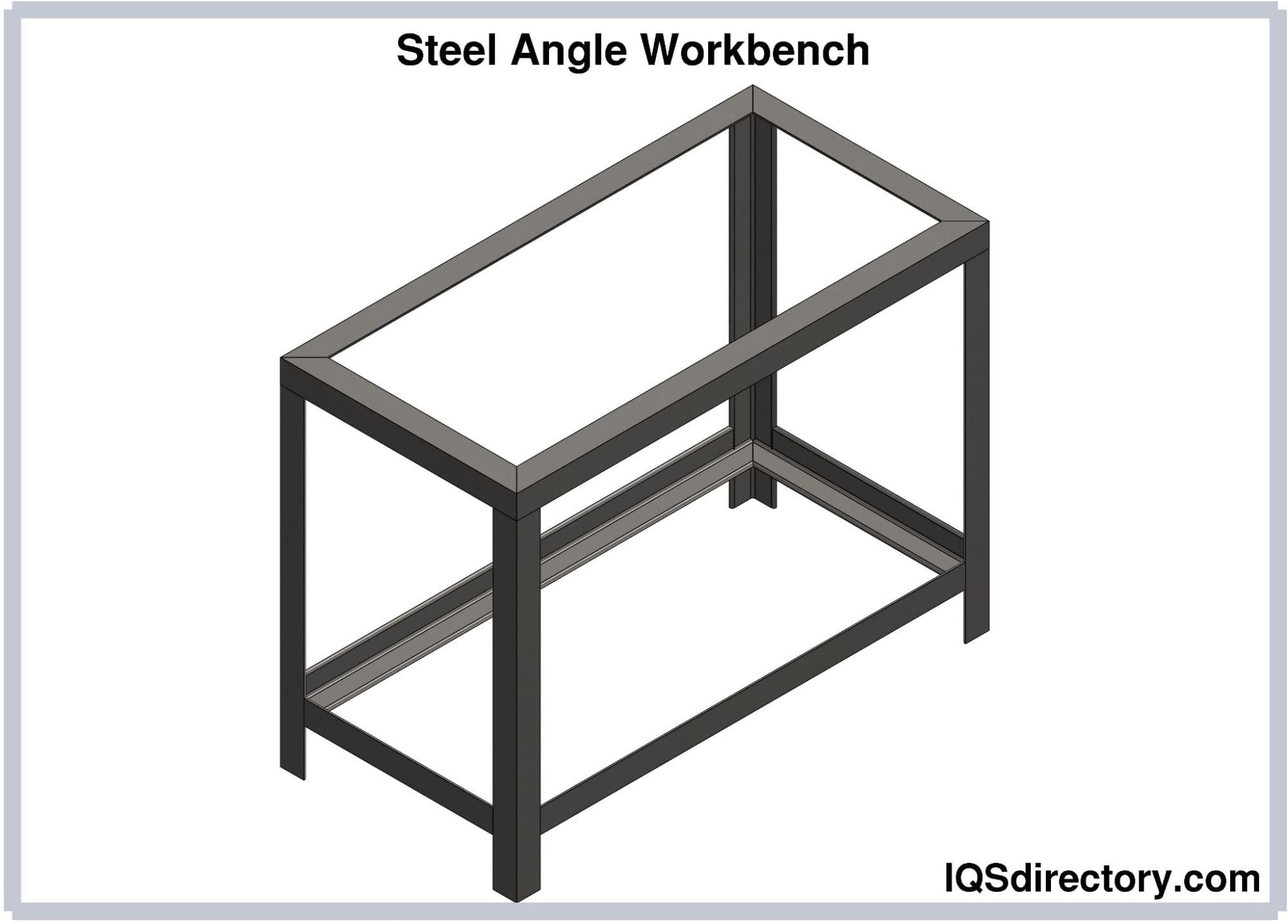

Frames

Framing various buildings and objects is a common application for steel angles. It is possible to build the basic design, which consists of an equal (or non-equal) angled L-shaped cross-section with two opposing legs, to get the desired look. A steel angle can have several apertures made on it using metal stamping or punching, for example, to provide a decorative framing element. Steel angle framing may also hold handrails, utility carts, interior moldings, trims, paneling, cladding, and many more custom-built designs.

Equipment Manufacturing

Until now, steel, in one form or another, has been used to manufacture most electrical equipment.. Forklifts, bulldozers, road rollers, and excavators are a few examples of powerful machines that use steel angles. Steel angles may even reinforce home appliances; their distinctive form protects the corners of stoves, ovens, washing machines, and dryers. Steel angles have significantly reduced costs for both equipment manufacturers and consumers. For instance, manufacturers rely on cheap and simple-to-produce material. Steel is also thought to be easily accessible and may be used again without losing any of its chemical or physical qualities.

Benefits of Steel Angles

Sustainability

Contrary to appearances, steel is among the most environmentally friendly building and construction materials. Steel is among the most recyclable materials, with about 90% of steel being made from recycled components. Steel is entirely recyclable and requires little processing, which has no effect on its potential to be reused. The carbon footprint of steel has roughly lowered by 50% during the past ten years. The quantity of energy needed to produce steel has dramatically decreased during the last 30 years. Very little water is used in the production of steel.

Cost

Steel is typically the most cost-effective construction material. Over the past 30 years, productivity rates have risen significantly due to advancements in steel manufacturing methods. Steel is a far more cost-effective basic material since it can be manufactured in less time and as a singleton. The cost of steel is finally dropping significantly because of advancements in steel manufacturing and finishing methods.

Strength

Because it can be twisted and shaped into many different shapes, steel is among the strongest construction materials in terms of structural strength. The chemical composition, production process, and heat treatment of steel are only a few variables that affect its mechanical properties. Construction steel primarily consists of iron, but additional alloys like manganese and niobium may greatly increase the steel's strength.

Although adding these elements may make steel stronger, it may also affect other properties like elasticity and weldability. Mechanical processing also impacts steel's overall strength; in principle, the more steel gets "rolled," the more robust it becomes.

Choosing the Correct Steel Angle Company

To make sure you have the most productive outcome when purchasing steel angles from a steel angle company, it is important to compare at least 5 companies using our steel angle directory. Each steel angle company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each steel angle company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple steel angle companies with the same message.

Cold Headed Parts

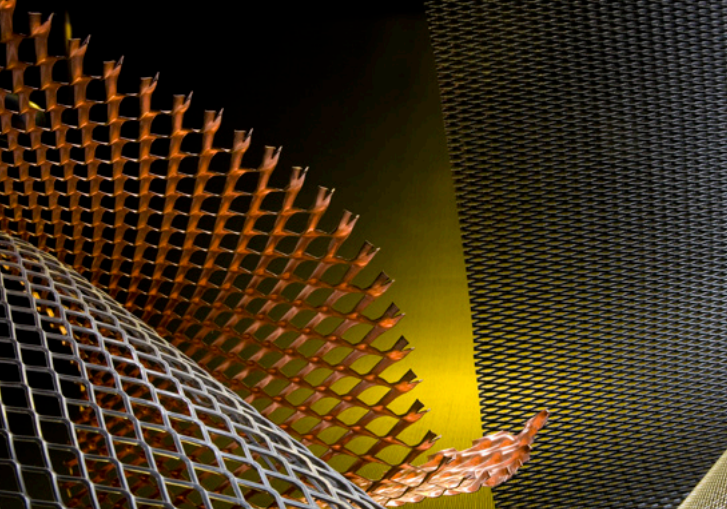

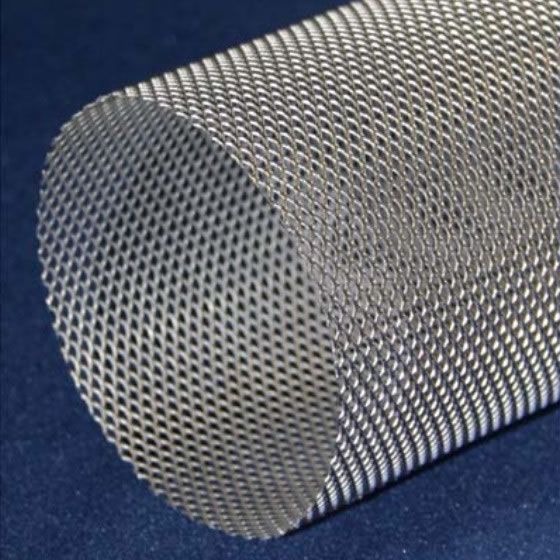

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services