Metal molding (aka metal molding in some parts of the United States) dates back a long time as people have made numerous products, tools, and other metal products for thousands of years through this process. Since its inception, metal molding has been evolving with the development of new processes, the use of different types of material to mold, and different molding conditions. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Metal Molding Companies

Metal molding is an integral chapter in the vast and diverse topic of molding. Numerous processes are incorporated into metal molding. Through the use of these processes, metal can be molded into any desired shape and size.

What is Metal Molding?

In the metalworking process known as metal molding, finely powdered metal is combined with a binding material to form a "feedstock" that is then molded and solidified via injection molding. High-volume, complex items can be formed using metal molding in only one stage. Following molding, these parts undergo conditioning processes to remove the binder and densify the powders. The finished goods produced through this process are utilized in numerous fields and applications.

Metal molding makes it possible to produce complicated high-volume items at a low cost. It guarantees a shorter production time than investment casting. Moreover, it also enables the production of net-shaped products including rubbers and sprues.

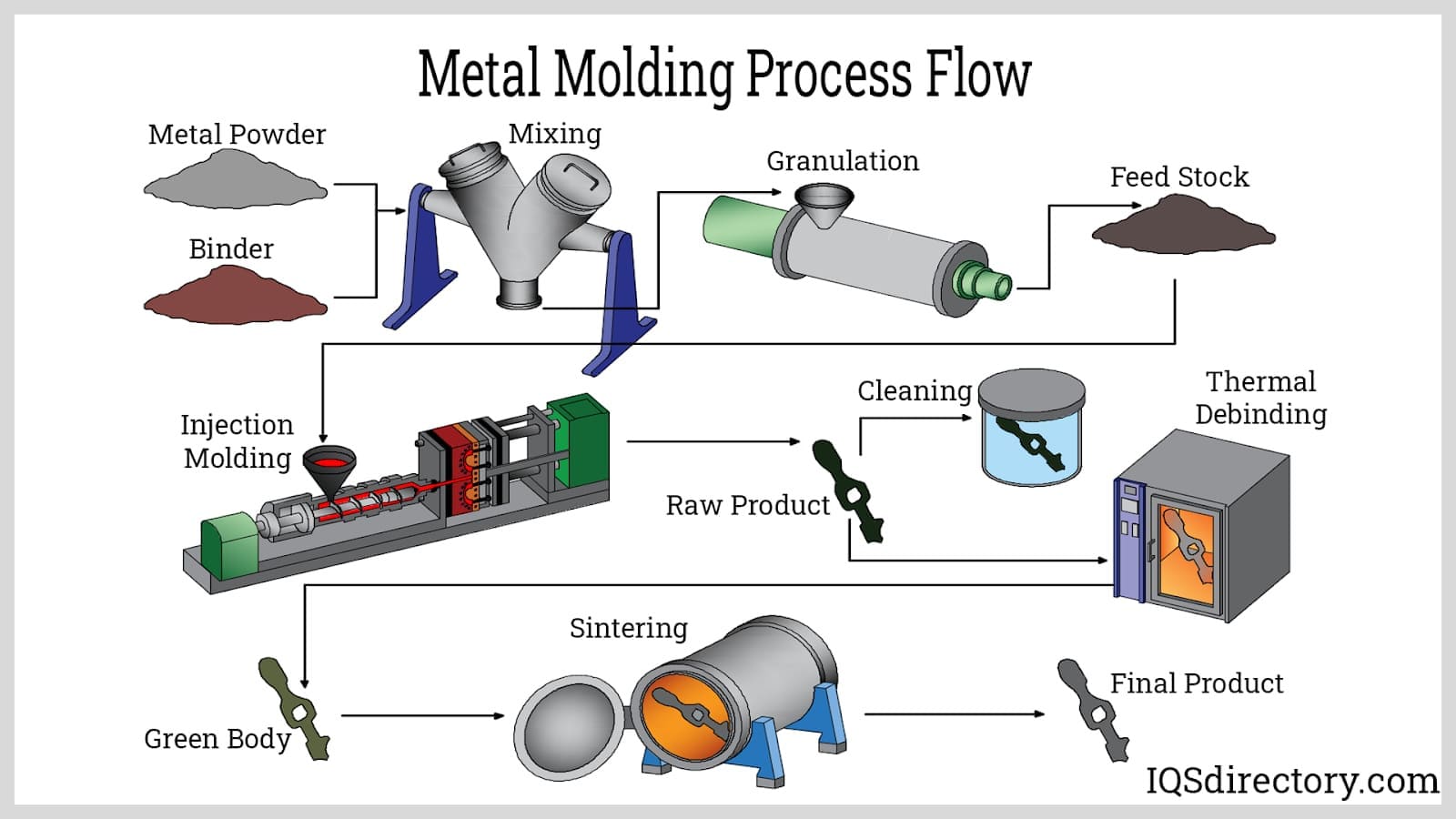

Process of Metal Molding

Below are the steps involved in the metal molding process:

Feedstock Preparation

Metal powders and thermoplastic binders are the main raw materials used in metal injection molding. After injection molding, the binder must be removed from the finished items as it is only used as intermediate processing assistance. The powder's properties determine the ultimate qualities of the metal injection molded product. The blended powder mix is processed at a high temperature into the plasticized binder material to create the feedstock using a kneader or shear roll extruder. This so-called feedstock is just an intermediate product. It is often granulated, with the typical granule size in the plastic injection molding industry being several millimeters.

Injection Molding

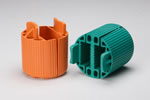

The second step in metal molding is operating the injection molding machine. The injection molding process used to make metal parts is analogous to the process used to form plastic parts. Therefore, the wide diversity of the metal parts produced is similar to that of plastic components created using injection molding.

Removal of Binder Material

After that, the binder material is removed to produce parts containing a series of interconnected pores but still preserve these components' individual shapes. There is frequently still some binder material in the areas binding the metal powder particles together after the binder removal procedure. Still, this pore network allows the binder to evaporate fast during the first stage of sintering, as sintering necks begin to form between the metallic particles.

Sintering

Most of the pore volume previously filled by the binder is eliminated during the sintering process.

Applications of Metal molding

Below are the applications of metal molding:

- Transport: automobile, aerospace, railways, and shipping

- Heavy equipment: construction, farming, and mining

- Machine tools: machining, casting, plastics molding, forging, extrusion, and forming

- Plant machinery: chemical, petroleum, paper, sugar, textile, steel, and thermal plants

- Defense: vehicles, artillery, munitions, storage, and supporting equipment

Cold Headed Parts

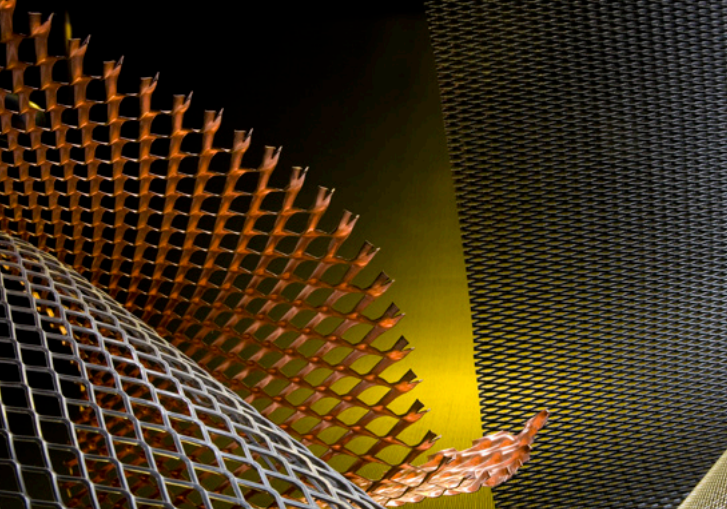

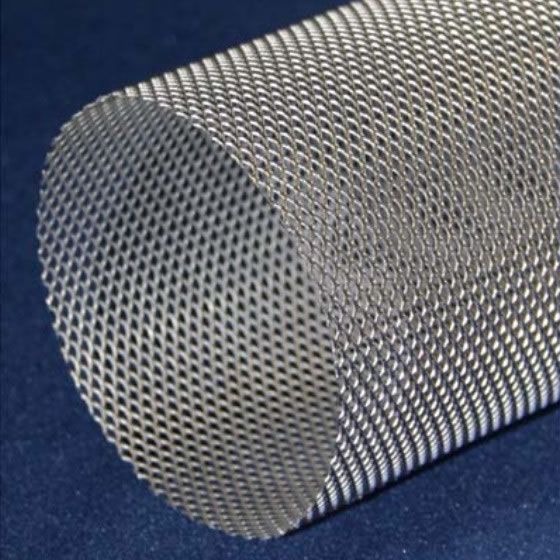

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services