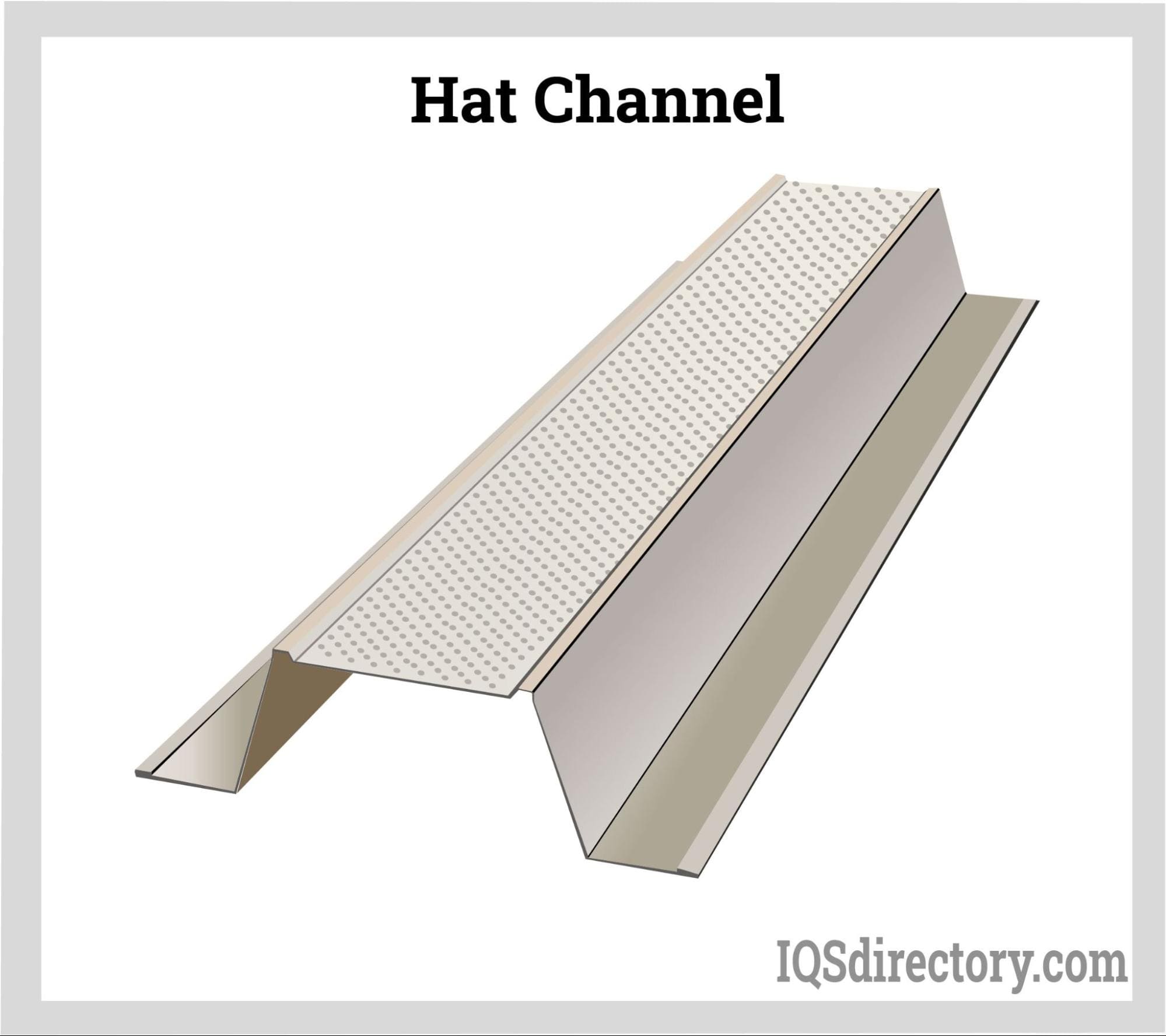

The term “hat channels” refers to the geometry of these channels. Hat channels are sometimes referred to as omega-sections or sub-girts, particularly in the housing and building industries due to their obvious resemblance in cross-section to a man’s top hat. A corrosion-resistant framing component known as a hat channel is used to fur out walls in masonry and ceiling installations. Hat channels have a metal component with a groove ideal for leveling out walls. Read More…

ISO 9001:2008 certified manufacturer specializing in custom roll forming. Unique profiles are run in gauges from 0.005" to 0.165" and widths up to 48" on 35 lines. Adding in-line operations may enhance your product.

Johnson Bros. is a leading manufacturer when it comes to roll forming metals, pre-finished and plain. Such as profiles, U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, and more.

With over 50 years of experience, United Roll Forming specializes in roll forming for a variety of industries. Our products are the result of state-of-the-art machines that provide both quality and efficiency.

Producing five different standard products, as well as complicated roll forming sections and secondary operations such as notching, punching and fabricating, is Roller Die & Forming Company, Inc.

Premier Products of Racine is a full-service company established in 1999 that provides custom roll formed products for applications such as outdoor appliances, tanker trucks, and office furniture.

More Hat Channel Companies

Hats provide flat surfaces for attachment and frequently have mounting holes and notches. Masons and builders frequently employ hat and Z channels to level uneven walls or ceilings. The channel also has the added benefit of protecting the interior and outdoor frame applications against corrosion, moisture, and fire. Additionally, ergonomically sound, the design makes for a hassle-free installation process.

Steel and aluminum are only a few materials used to create hat channels. Adding a hat channel can increase an existing wall's acoustic performance and achieve high Sound Transmission Class (STC) ratings, depending on how many layers of drywall are added to the hat channel.

Types of Hat Channels

Steel Hat Channels

Steel hat channels have replaced conventional wood furring channels as a favorite among masons. Due to its resistance to fire and noise, steel is a material that many builders favor. In addition, steel is better for supporting structures and is simple to install without harming the surrounding materials.

Galvanized steel hat channels can be installed in drop ceilings or walls. Steel channels are available in heavier gauges. Since they are galvanized to prevent corrosion and fires, they are reliable and long-lasting for attaching to the ceiling or walls. Additionally, installing them is quite simple. This increases the loading capacity. Steel channels are the most resilient, sturdy, and dependable material when constructing a heavy-duty basement.

Aluminum Hat Channels

Hat channels made of aluminum may perform all the same tasks as hat channels made of wood or steel. To provide an air gap between interior and exterior walls, siding for exterior wall cladding, curtain walls, rain-screen installations, aluminum hat channels, and furring channels are popular alternatives. A building structure's hat channels are a foundation for installing water diversion systems and thermal efficiency for affordable heating, cooling, and appearance solutions.

Aluminum hat channels can be used as a transition between building materials because they can be used as a design feature as a decorative reveal between wall panels, sheetrock, or tile products. One can guarantee that the material spacing and visual lines stay accurate and straight by using hat channels as an extruding reveal or shadow reveal. To improve any design, aluminum hat channel reveals and accent trim can be custom anodized or powder coated with a beautiful finish.

The Manufacturing of Hat Channels

- Hat channels are designed, engineered, and then built in metal fabrication shops by experts following predetermined or unique specifications. While most manufacturers of hat channels use a standard mold at high temperatures to form the metal into the proper shape, Cold roll forming gradually presses the metal into the shape of the hat without heating it.

- A team of in-house engineers from some manufacturers, especially bigger industrial ones that make hat channels for big clients, can develop unique hat channels to adhere to specific construction requirements. The engineering team will then collaborate with the production managers to design an effective procedure for constructing these unique hat channels with their tools. Process improvement is crucial for speed and cost management. Following production, hat channels are swiftly delivered to vendors and craftspeople for use in construction projects. In addition, these hat channels are lightweight and can be transported in large quantities by truck or train, making purchases practical for significant construction companies.

Comparison of Hat Channels with Other Channel Types

One of the various rolling items on the market is hat channels.

Adaptable Channel (RC Channels)

- A robust channel has a hat-like appearance but is divided down the middle. Hat channels resemble a fedora, whereas RC channels resemble a baseball cap more closely.

- Reduced sound levels can also be achieved with RC channels. It can also be highly useful for insulation, much like the hat version.

- On the other hand, RC channels are frequently less reliable and useful. In addition, although RC channels are attached to wall studs, any contact can negate their soundproofing properties.

- The lip on both end and the use of stronger materials make hat channels sturdy. In addition, the drywall can be kept from shifting with a hat channel. However, the fact that it has two sides with lips makes it less soundproof.

Channels with Z Furring

- Rigid insulation is frequently used in conjunction with Z furring channel. In addition, architects frequently use them on walls and ceilings for outside metal panels, plaster, and gypsum panels.

- Z channels, as opposed to hat channels, are screwed in, with one side of the flange up against the wall and the other hanging out. Hat channels and Z furring install both have the same effectiveness.

J channels

- J channels can be used to cover windows and doors exterior edges. In addition, they can be utilized to keep moisture out of unfavorable locations.

- Since J channels are intended for outside walls, they rarely interact with hat channels.

Choosing the Proper Hat Channels Company

To make sure you have the most positive outcome when purchasing hat channels from a hat channel company, it is important to compare at least 4 companies using our hat channel directory. Each hat channel company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each hat channel company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple hat channel companies with the same form.

Cold Headed Parts

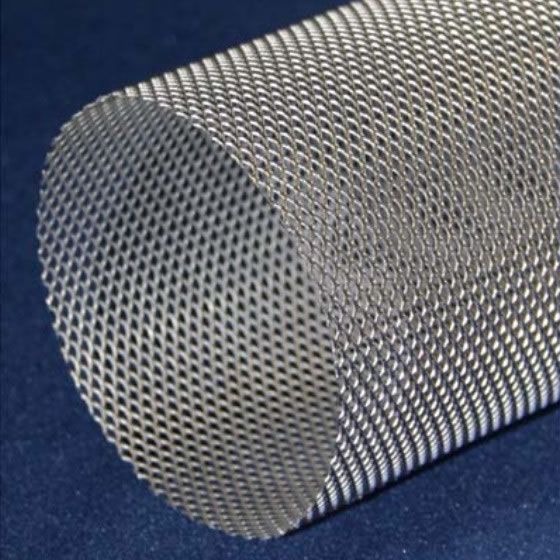

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services