Jamé Roll Form Products, Inc.

Jamé Roll Form Products, Inc.Request A Quote

Franklin Park, ILJamé Roll Form Products, Inc. is a leading provider of custom roll formed parts and metal fabrication services. With over 50 years of experience in the industry, Jamé Roll Form Products, Inc. has become a trusted partner for businesses in a wide range of industries, including automotive, construction, agriculture, and more. At the heart of Jamé Roll Form's business is their expertise in roll forming. Roll forming is a manufacturing process that involves bending metal sheets into specific shapes and profiles. Jamé Roll Form Products, Inc. has perfected this process, allowing them to produce high-quality, precise parts for their customers. Jamé Roll Form's capabilities are extensive. They have a wide variety of roll forming machines, each designed for specific types of parts and materials. This allows them to handle everything from simple parts to complex profiles and shapes, all with tight tolerances and high accuracy. One of the key benefits of working with Jamé Roll Form Products, Inc. is their ability to provide custom solutions for their customers. They work closely with their clients to understand their specific needs, and then develop tailored solutions that meet those needs. This includes everything from material selection to tooling design to production processes. In addition to their roll forming capabilities, Jamé Roll Form Products, Inc. also offers a range of secondary services to complement their primary business. These include stamping, punching, welding, and assembly services, all performed with the same level of precision and quality as their roll forming work. Overall, Jamé Roll Form Products, Inc. is a company with a rich history of roll forming expertise and a commitment to quality and customer satisfaction. Their extensive capabilities and custom solutions make them an ideal partner for businesses looking for reliable, high-quality roll formed parts and metal fabrication services.

Cold Headed Parts

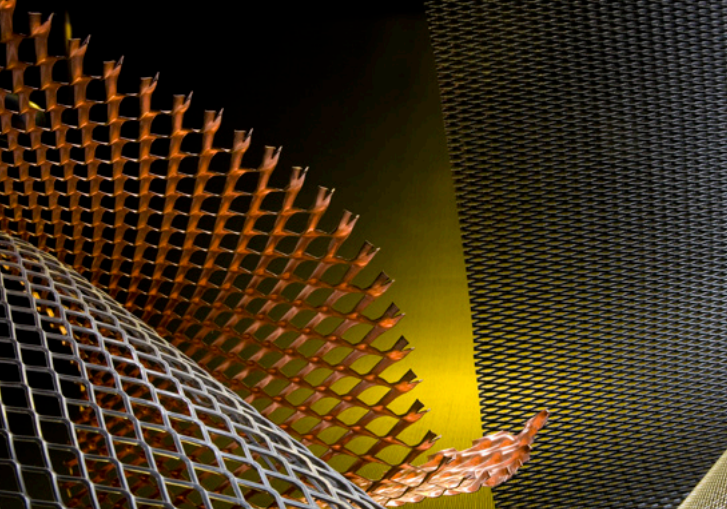

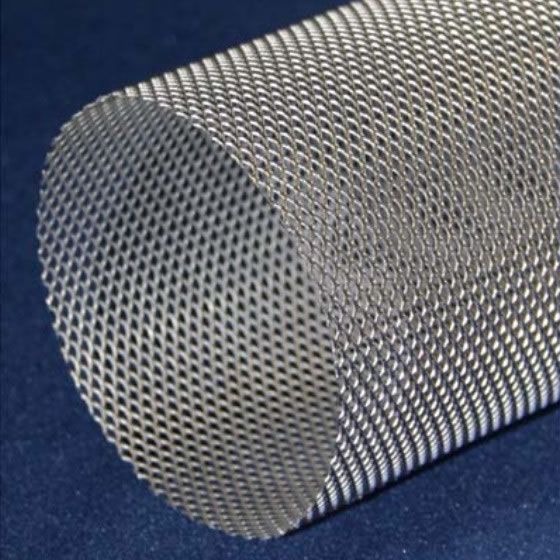

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services