LTC Roll & Engineering

LTC Roll & EngineeringRequest A Quote

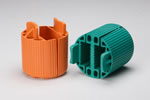

CLINTON TOWNSHIP, MI | 586-465-1023LTC Roll & Engineering, established in 1967, is a renowned full-service custom roll former with a rich history of delivering exceptional solutions. With headquarters and manufacturing facilities equipped with cutting-edge technology, LTC Roll & Engineering has become a trusted partner for clients seeking high-quality roll formed products. As a full-service provider, LTC Roll & Engineering offers a comprehensive range of products, services, and capabilities to meet diverse customer needs. Our core expertise lies in custom roll forming, and we excel at transforming various metals, including steel, aluminum, and stainless steel, into precise and complex shapes. We leverage our in-house design, tooling, and manufacturing capabilities to provide seamless solutions tailored to our customers' specific requirements. Our products encompass a wide range of applications across multiple industries. From automotive and construction to furniture and appliance manufacturing, LTC Roll & Engineering delivers innovative roll formed parts that are known for their exceptional quality and precision. Whether it's custom profiles, trim components, structural sections, or specialized parts, our experienced team is dedicated to producing products that meet the highest industry standards. At LTC Roll & Engineering, we understand that successful roll forming projects require more than just manufacturing capabilities. That's why we offer a comprehensive suite of services to support our customers throughout the entire process. From design consultation and prototyping to manufacturing and post-production support, our team of experts collaborates closely with clients, ensuring that their vision is translated into reality. With our in-house design and engineering capabilities, we work closely with clients to optimize their designs for roll forming, considering factors such as material selection, cost-efficiency, and performance. Our experienced tooling engineers use state-of-the-art software and equipment to create precise and durable tooling that ensures consistent quality in production. With a legacy spanning over five decades, LTC Roll & Engineering has established itself as a trusted partner for custom roll forming. We take pride in our ability to offer end-to-end solutions, from concept to production, all under one roof. When it comes to precision roll formed products, LTC Roll & Engineering is the preferred choice for quality, reliability, and exceptional customer service.

Cold Headed Parts

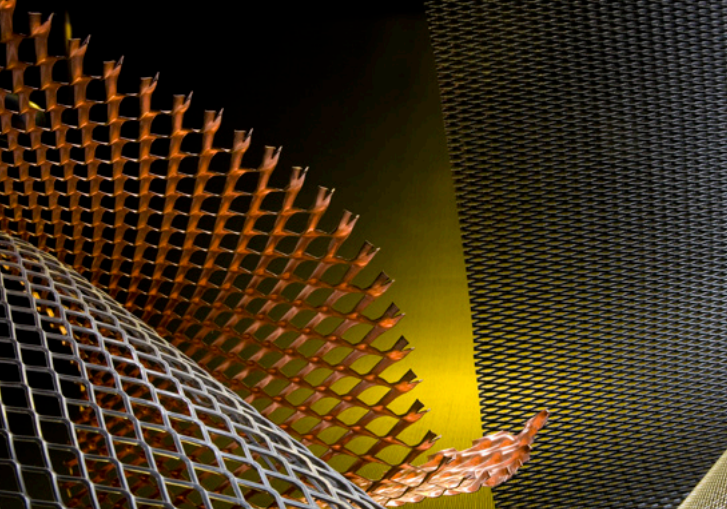

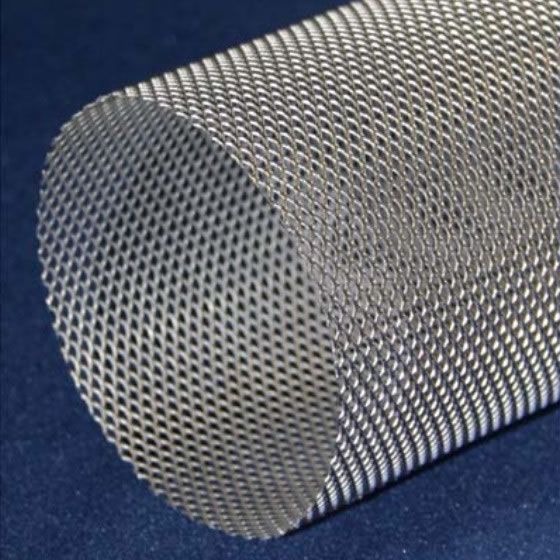

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services