Paramount Roll & Forming Inc.

Paramount Roll & Forming Inc.Request A Quote

Bellflower, CA | 562-944-6151https://www.paramountroll.com/

Paramount Roll & Forming Inc. is a highly specialized metal fabrication company based in Santa Fe Springs, California, that specializes in the production of roll formed parts for a wide range of industries. Founded in 1963, the company has extensive experience in the metalworking industry and is known for its high-quality products and exceptional customer service. Paramount Roll & Forming Inc.'s products are designed to meet the specific needs of its clients across a wide range of industries, including automotive, construction, aerospace, and electronics. The company's roll forming capabilities enable it to produce complex shapes and designs with consistent precision, ensuring that each product meets or exceeds the exact specifications of its clients. The company's roll formed parts include a wide range of products such as angles, channels, beams, rails, tubes, and other custom shapes. Paramount Roll & Forming Inc. can create roll formed parts from a variety of materials, including aluminum, brass, copper, steel, and stainless steel. The company's products are designed to withstand the most demanding conditions, ensuring that they provide long-lasting performance in even the harshest environments. Paramount Roll & Forming Inc.'s state-of-the-art equipment includes multiple roll forming machines, press brakes, and punching machines, which allow the company to produce custom parts quickly and efficiently. The company also has an in-house tool and die shop, which allows it to design and manufacture custom tooling for each specific job, resulting in greater precision and faster turnaround times. The company's service capabilities are focused on providing personalized solutions that meet the unique needs of each client. Paramount Roll & Forming Inc. has an experienced team of engineers and technicians who work closely with clients to design and manufacture roll formed parts that meet their specific requirements. The company's team can also provide prototyping and testing services, allowing clients to evaluate products before committing to full production. In addition to its manufacturing capabilities, Paramount Roll & Forming Inc. also offers a range of value-added services to its clients, including finishing, packaging, and shipping. The company can provide custom finishing options such as painting, plating, and powder coating, ensuring that each product meets the exact specifications of its clients. Overall, Paramount Roll & Forming Inc. is a leading provider of roll formed parts, offering exceptional products and services to clients across a wide range of industries. The company's commitment to quality, precision, and customer service has earned it a reputation as a trusted partner for businesses seeking custom metal fabrication solutions.

Cold Headed Parts

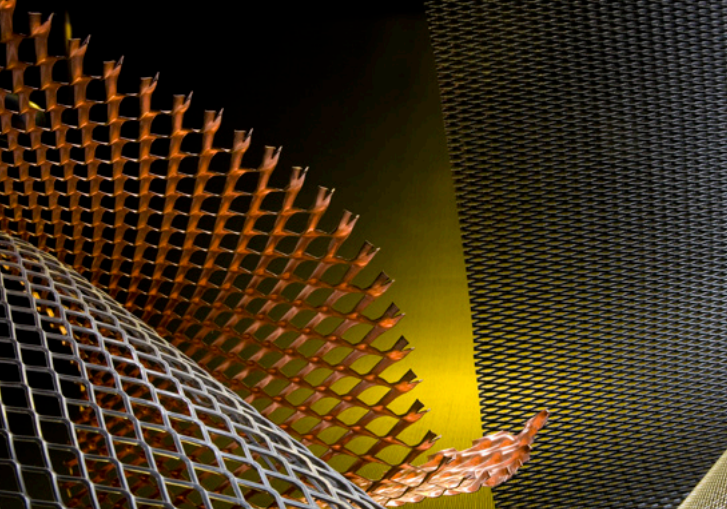

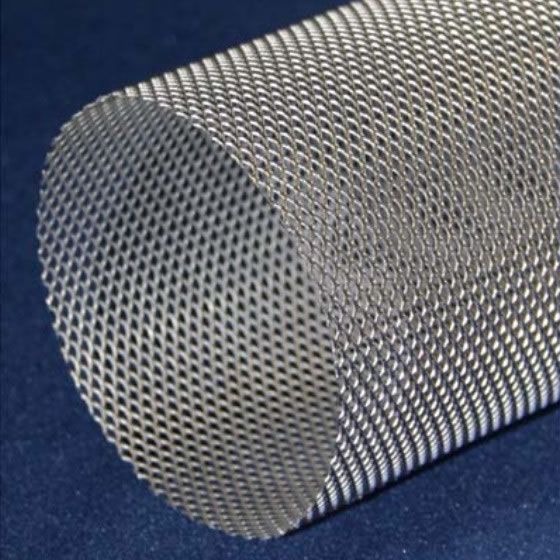

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services