Redall Industries, Inc.

Redall Industries, Inc.Request A Quote

Yale, MIRedall Industries, Inc. is a leading manufacturer of custom roll-formed parts for a wide range of industries, including construction, transportation, and energy. With over 40 years of experience, the company is known for its expertise, quality products, and exceptional customer service. Redall Industries, Inc. uses state-of-the-art roll-forming technology to produce precision parts from a variety of materials, including steel, aluminum, and copper. Their roll-forming process involves passing flat sheets of metal through a series of rollers to create complex shapes and profiles that meet their clients' exact specifications. The company's team of experienced engineers and technicians work closely with clients to develop custom roll-formed parts that meet their unique requirements. Redall Industries, Inc. offers a comprehensive range of services, including design and engineering, prototyping, production, and finishing. Redall Industries' roll-formed parts are used in a variety of applications, such as building products, transportation components, and energy infrastructure. Their products are known for their strength, durability, and consistency, and they meet or exceed industry standards for quality and performance. In addition to roll-formed parts, Redall Industries, Inc. offers a full range of metal fabrication services, including bending, welding, and assembly. They are committed to providing their clients with exceptional customer service and support, offering flexible production schedules, fast turnaround times, and customized solutions to meet their clients' specific needs. Redall Industries, Inc. is also dedicated to continuous improvement and innovation. They invest heavily in research and development, exploring new materials and techniques to create products that meet the changing needs of their clients and the industry. Overall, Redall Industries, Inc. is a trusted partner for all types of metal fabrication needs. Their focus on roll-formed parts, combined with their extensive experience, advanced technology, and commitment to quality and customer service, ensures that clients receive the best possible products and services.

Cold Headed Parts

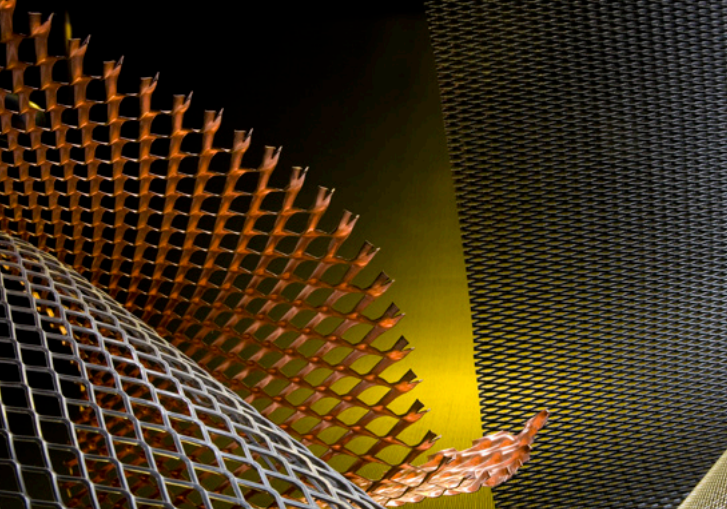

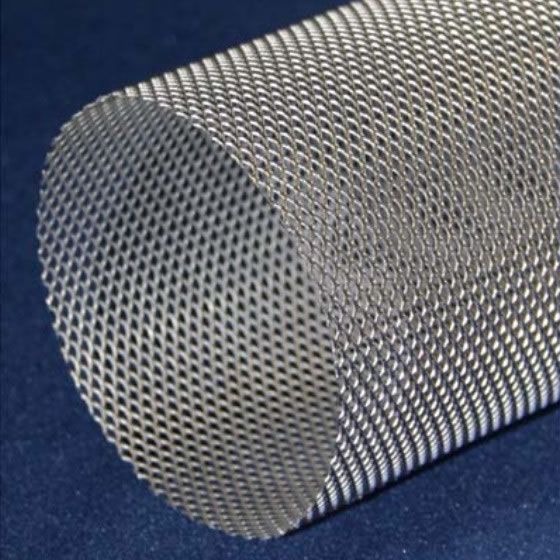

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services