WG Corporation/OMCO

WG Corporation/OMCORequest A Quote

Morgantown, PAWG Corporation, a subsidiary of OMCO, is a premier provider of custom roll forming solutions based in Morgantown, Pennsylvania. With a rich heritage and a commitment to excellence, we have established ourselves as a trusted partner for industries seeking high-quality, precision-engineered roll formed products. At WG Corporation/OMCO, our core focus is on custom roll forming, where we leverage advanced technology and industry expertise to transform flat metal coils into complex, precision-engineered profiles. Our state-of-the-art manufacturing facility, coupled with our skilled engineers and technicians, enables us to produce a wide range of roll formed products tailored to meet the specific needs of our clients. Our product portfolio encompasses a diverse array of roll formed parts, including but not limited to channels, angles, C-sections, Z-sections, hat sections, and custom profiles. We work closely with our customers to understand their unique requirements, ensuring that each roll formed product we deliver adheres to the highest quality standards and meets their exact specifications. Our manufacturing capabilities are second to none. Equipped with advanced roll forming machines, precision tooling, and an in-house tool and die shop, we have the expertise and resources to efficiently handle projects of all sizes and complexities. We specialize in working with various metals, including steel, stainless steel, aluminum, and specialty alloys, allowing us to cater to a wide range of industries and applications. WG Corporation/OMCO is driven by a commitment to customization and innovation. Our experienced engineers work closely with clients to develop tailored solutions that meet their unique needs. Whether it's modifying an existing profile or designing a completely new shape, we have the flexibility and expertise to bring our customers' visions to life. With a focus on precision and attention to detail, we ensure that the final roll formed products perfectly align with our clients' specifications.

Cold Headed Parts

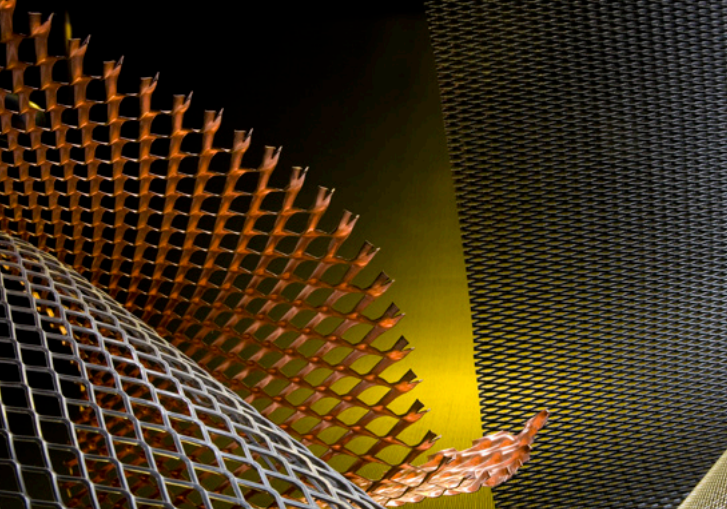

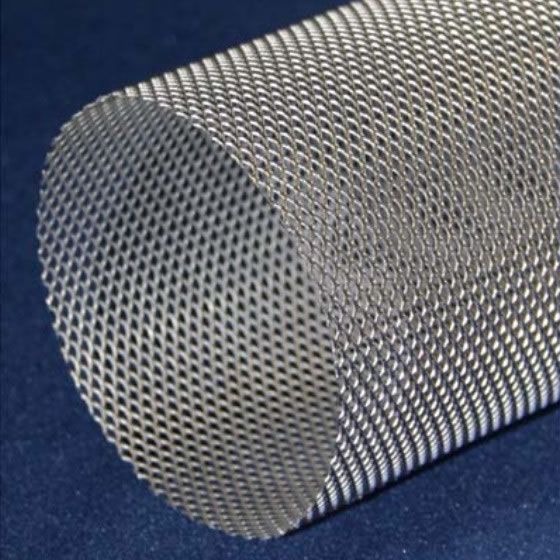

Cold Headed Parts Expanded Metals

Expanded Metals Metal Spinning

Metal Spinning Powdered Metal Parts

Powdered Metal Parts Roll Forming

Roll Forming Springs

Springs Wire Forms

Wire Forms Wire Mesh

Wire Mesh Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

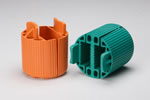

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services